Copper - Aluminum Pipe Air Conditioning Connection Tubing 1060 H14

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO20000 |

| Model Number | 1060 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Air Conditioning Connection Pipe |

|---|---|---|---|

| Model Number | 1060 | State | H14 |

| Outside Diameter/mm | 4-22 | Thickness/mm | 0.24-2.00 |

| Shape | Coil | Applications | Dehumidifier ,Cold Dry Machine, Warm Air Blower |

| High Light | 1060 ac water pipe connection,ac water pipe connection 1060 H14,portable ac exhaust pipe Anti corrosion |

||

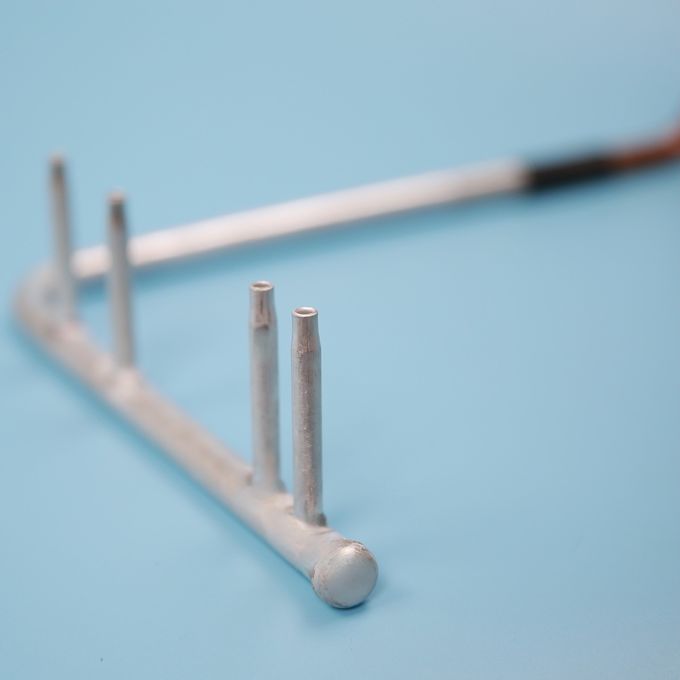

Copper-Aluminum Pipe Air Conditioning Connection Tubing 1060 H14

Product Description:

It can produce 1 series of industrial aluminum alloy 1060,1050,3070,3003 aluminum manganese alloy product specifications, according to customer needs to produce a variety of length specifications and bending diameter, plastic sealing carton or wooden support packaging, easy transportation.

The purpose of the special aluminum tubes and fitting connectors that connect the outdoor unit to the indoor unit is to connect the indoor unit to the outdoor unit.2 The refrigerant (Freon, commonly known as snow) passes through the connecting tubes.

Features:

1, copper and aluminum composite tube of the double-layer structure of its anti-vibration fatigue strength for the copper tube twice.

2, copper-clad aluminum air conditioner connecting tube compared with copper tube can save a lot of procurement costs.

3, copper clad aluminum tube is also very suitable for manufacturing evaporator, can get very good evaporation effect. Compared with copper tube, only the brazing method is changed.

Applications:

evaporimeter

condensator

dehumidifier

Cold dry machine

warm air blower

etc.

Techical Parameters:

Mechanical properties and structure

1, the tensile strength of the bimetallic composite pipe is 150-160MPa, elongation is 35-40%; pressure resistance of 15MPa or more.

2, copper-clad aluminum tube for the integration of materials, copper and aluminum can not be separated, like copper pipe bending, flaring, softness and copper pipe.

3, the section of the pipe contains copper and aluminum weight ratio of 60/40, the pipe outer diameter, wall thickness, specifications and the same as the original copper pipe.

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/m m | ||

| 1050,1060,1070 | M(O) | 4-22 | 0.24-2.00 |

| H14 | |||

| 3003,3103 | M(O) | ||

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Support and Services:

We can provide technical support and services for the use of aluminum pipes, including technical guidance, assistance in production, etc. Our experienced technicians can assist you with any problems your product may encounter. We also provide regular after-sales service to ensure that your products are always run at the highest efficiency. We are proud of our work and strive to provide the best customer service.

If you have any questions or concerns about the product or your use, please feel free to contact us. We will always give you the answers you need.

FAQ.:

Q1: aluminum alloy pipe compared with copper pipe, advantages and disadvantages?

A1: Aluminum pipe cost low ductility, but easy to corrosion. Copper pipes have good thermal conductivity and corrosion resistance, but the installation, preservation and transportation are not easy and the cost is high.

Q2: What should be noted in the installation of the air conditioning connection pipe?

A2: The alloy pipe is easy to install, but the link of copper and aluminum after a long time of chemical changes, will cause electrocouple corrosion.

Q3: How to deal with the corrosion problem?

A3: Our products use special corrosion resistant alloy, and the corrosion resistance effect is greatly improved compared with ordinary aluminum alloy. The corrosion resistance experiment is> 1000 hours, which greatly improves the service life of the product.

Q 4: What state and performance of aluminum pipe and aluminum alloy pipe can be produced?

A 4: It can produce performance products from hard state to soft state and interval.