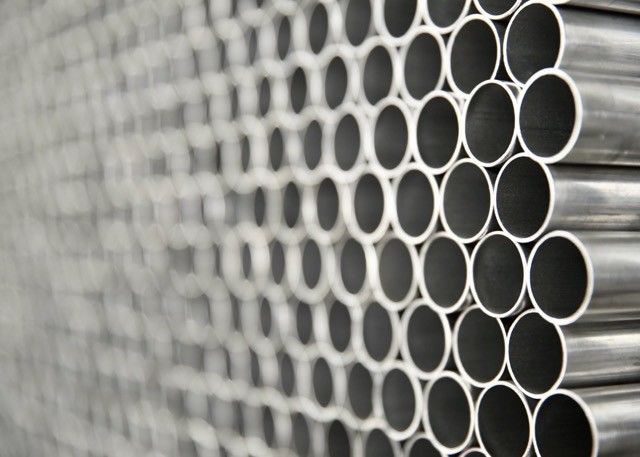

Coil Tube Insulated Copper-Aluminum Pipe Air Conditioning Connection Tubing 3/8"

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO20000 |

| Model Number | 3/8" |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Air Conditioning Connection Tubing | O.D. | 3/8" |

|---|---|---|---|

| Maximun Stress(Copper) | 1070psi | Maximun Stress(Alloy Tube) | 3820psi |

| Pressure Rate | 357% | Specification | 1P(1/4"-3/8") Or 3P(3/8"-5/8") |

| O.D./mm | 6.35*9.52 Or 9.52*15.88 | Applications Model | KF23 KF25 KF26 KF27 KFR23 KFR25 KFR26 KF60 KF70 KF71 KF72 KFR61 KFR70 KFR71 |

| High Light | Insulated air conditioning pipe,air conditioning pipe 3/8in,portable air conditioner tube 1070psi |

||

Coil Tube Insulated Copper-Aluminum Pipe Air Conditioning Connection Tubing 3/8"

Product Description:

Copper and aluminum connection tubing for air conditioners:

Cotton Insulation

Be thicker to prevent fires.

Copper Tubing

The material is made of pure copper.

Aluminum Pipe

1070 aluminum tubing with good ductility and thermal conductivity is used.

Tube that can be shrunk with heat

The main material is PE, which provides better protection for copper and aluminum tubes, prevents rust and corrosion, and increases the durability of aluminum tubes.

Brass Nuts A set of 4 copper nuts for air conditioning connection pipe, nut material for brass, thickened sturdy, and easy to use.

Features :

The bursting pressure figure is 4-6 times greater than the typical strength.

1. A double-layer copper and aluminum composite tube with anti-vibration fatigue strength for the copper tube.

2. When compared to copper tubes, copper-clad aluminum air conditioner connection tubes can save a significant amount of money on procurement prices.

3. Copper coated aluminum tube is also an excellent material for making evaporators since it has a high evaporation rate. Only the brazing procedure differs from that of copper tube.

Applications:

evaporimeter

condensator

dehumidifier

Cold dry machine

warm air blower

etc.

Techical Parameters:

| Model Number(D.O.) | Maximum Stress | Pressure Rate/% | |

| Copper/psi | Alloy Tube/psi | ||

| 1/4” | 1650 | 5510 | 334 |

| 3/8” | 1070 | 3820 | 375 |

| 1/2” | 780 | 3180 | 408 |

| 5/8” | 610 | 3170 | 520 |

(Technical requirements refer to national standards or customer technical quality requirements for production)

Support and Services:

We can provide technical support and services for the use of aluminum pipes, including technical guidance, assistance in production, etc. Our experienced technicians can assist you with any problems your product may encounter. We also provide regular after-sales service to ensure that your products are always run at the highest efficiency. We are proud of our work and strive to provide the best customer service.

If you have any questions or concerns about the product or your use, please feel free to contact us. We will always give you the answers you need.

FAQ.:

Q1: aluminum alloy pipe compared with copper pipe, advantages and disadvantages?

A1: Aluminum pipe cost low ductility, but easy to corrosion. Copper pipes have good thermal conductivity and corrosion resistance, but the installation, preservation and transportation are not easy and the cost is high.

Q2: What should be noted in the installation of the air conditioning connection pipe?

A2: The alloy pipe is easy to install, but the link of copper and aluminum after a long time of chemical changes, will cause electrocouple corrosion.

Q3: How to deal with the corrosion problem?

A3: Our products use special corrosion resistant alloy, and the corrosion resistance effect is greatly improved compared with ordinary aluminum alloy. The corrosion resistance experiment is> 1000 hours, which greatly improves the service life of the product.

Q 4: What state and performance of aluminum pipe and aluminum alloy pipe can be produced?

A 4: It can produce performance products from hard state to soft state and interval.