Copper & Aluminum AC Connection Pipe For Air Conditioners With Cotton Insulation 5/8"

| Place of Origin | Changzhou, China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 5/8" |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Air Conditioning Connection Tubing | O.D. | 5/8" |

|---|---|---|---|

| Maximun Stress(Copper) | 610psi | Maximun Stress(Alloy Tube) | 3170psi |

| Pressure Rate | 520% | Specification | 1P(1/4"-3/8") Or 3P(3/8"-5/8") |

| O.D./mm | 6.35*9.52 Or 9.52*15.88 | Applications Model | KF60 KF70 KF71 KF72 KFR61 KFR70 KFR71 |

| High Light | 610psi AC Connection Pipe,AC Connection Pipe 3170psi,air condition pipe 5/8in |

||

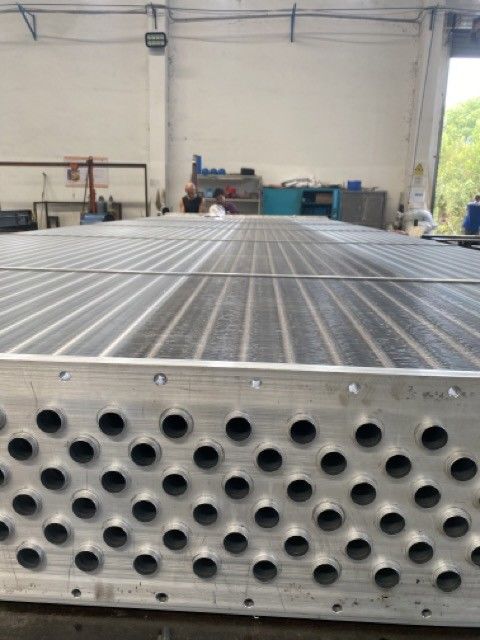

Copper & Aluminum Connection Pipe for Air Conditioners with Cotton Insulation5/8":

Cotton Insulation

Be thicker to prevent fires.

Copper Tubing

The material is made of pure copper.

Aluminum Pipe

1070 aluminum tubing with good ductility and thermal conductivity is used.

Tube that can be shrunk with heat

The main material is PE, which provides better protection for copper and aluminum tubes, prevents rust and corrosion, and increases the durability of aluminum tubes.

Brass Nuts A set of 4 copper nuts for air conditioning connection pipe, nut material for brass, thickened sturdy, and easy to use.

Features :

The bursting pressure figure is 4-6 times greater than the typical strength.

1. A double-layer copper and aluminum composite tube with anti-vibration fatigue strength for the copper tube.

2. When compared to copper tubes, copper-clad aluminum air conditioner connection tubes can save a significant amount of money on procurement prices.

3. Copper coated aluminum tube is also an excellent material for making evaporators since it has a high evaporation rate. Only the brazing procedure differs from that of copper tube.

Copper-aluminum connecting pipe technical standards:

(1) The welding joints must be free of defects such as pores, cracks, slag, burrs, and burns. The two metals, copper and aluminum, should be completely fused with no obvious oxide film, and there should be no significant reduction in plug holes (Φ6.3 holes larger than 3.0 mm).

(2) The air tightness requirements of the copper-aluminum connecting pipe are very strict. Use a high pressure of 4.0MPa for a 5-minute test without any leakage.

(3) After passing the air tightness inspection, the pressure needs to be slowly increased to 13MPa and maintained for 1 minute. There should be no cracks in the copper-aluminum connecting pipe.

(4) The bending performance requirements of the copper-aluminum connecting pipe are very high. The sample is bent into a bending core that is twice the nominal diameter of the pipe. After bending 180 degrees, the pipe must not produce wrinkles or cracks.

(5) The tensile strength of the copper-aluminum connecting pipe is required to be between 65-118mpa, the tensile force part is on the side of the aluminum pipe, and the welding seam is above 10mm.

(6) The sealing performance requirements of the copper-aluminum connecting pipe are very high. KTG shrinks well, the sealing accessories have melted and are completely wrapped in the copper-aluminum joint, and the seal cannot rotate.

Our advantage:

1. Long life: The outer surface of the copper-aluminum connecting pipe is treated with cross-linked polyethylene (heat pipe) for anti-corrosion treatment, which effectively prevents corrosion of the aluminum pipe by water and humid air. The use of this anti-corrosion treatment technology ensures that the service life of the copper-aluminum connecting pipe can reach more than 20 years.

2. Cost optimization and anti-oxidation: There is no oxidation corrosion of knots and hills between one end of the copper-aluminum connecting pipe and the valve, which can easily cause quality problems. By using copper and aluminum tubes to connect the two ends of the brass, we avoid this problem and achieve the purpose of reducing costs.

3. High cleanliness: Since the connection between the copper tube and the aluminum tube does not require welding, but is connected by cold connection, this avoids the generation of surface oxides caused by all high-temperature welding. Therefore, the copper-aluminum connecting pipe can meet the cleaning requirements of the cooling pipe without any additional processing.

4. Optimization of thermal insulation performance: The air-conditioning connecting pipes need to have excellent thermal insulation properties, and the thermal insulation performance of the copper-aluminum connecting pipes has been further improved, thus helping to improve the energy efficiency of the air conditioner.

5. Excellent performance: The burst pressure of the copper-aluminum connecting pipe is exactly the same as the allowed burst pressure of the copper connecting pipe. The design pressure of both is 13.0Mpa, showing excellent performance.

6. Excellent terminal performance and convenient installation and movement: Compared with brass, aluminum has better terminal properties. At the same time, the installation and movement of the copper-aluminum connecting pipe are also more convenient, bringing convenience to practical applications.

Applications:

evaporimeter

condensator

dehumidifier

Cold dry machine

warm air blower

etc.

Techical Parameters:

| Model Number(D.O.) | Maximum Stress | Pressure Rate/% | |

| Copper/psi | Alloy Tube/psi | ||

| 1/4” | 1650 | 5510 | 334 |

| 3/8” | 1070 | 3820 | 375 |

| 1/2” | 780 | 3180 | 408 |

| 5/8” | 610 | 3170 | 520 |

(Technical requirements refer to national standards or customer technical quality requirements for production)

Support and Services:

We can provide technical support and services for the use of aluminum pipes, including technical guidance, assistance in production, etc. Our experienced technicians can assist you with any problems your product may encounter. We also provide regular after-sales service to ensure that your products are always run at the highest efficiency. We are proud of our work and strive to provide the best customer service.

If you have any questions or concerns about the product or your use, please feel free to contact us. We will always give you the answers you need.

FAQ.:

Q1: aluminum alloy pipe compared with copper pipe, advantages and disadvantages?

A1: Aluminum pipe cost low ductility, but easy to corrosion. Copper pipes have good thermal conductivity and corrosion resistance, but the installation, preservation and transportation are not easy and the cost is high.

Q2: What should be noted in the installation of the air conditioning connection pipe?

A2: The alloy pipe is easy to install, but the link of copper and aluminum after a long time of chemical changes, will cause electrocouple corrosion.

Q3: How to deal with the corrosion problem?

A3: Our products use special corrosion resistant alloy, and the corrosion resistance effect is greatly improved compared with ordinary aluminum alloy. The corrosion resistance experiment is> 1000 hours, which greatly improves the service life of the product.

Q 4: What state and performance of aluminum pipe and aluminum alloy pipe can be produced?

A 4: It can produce performance products from hard state to soft state and interval.