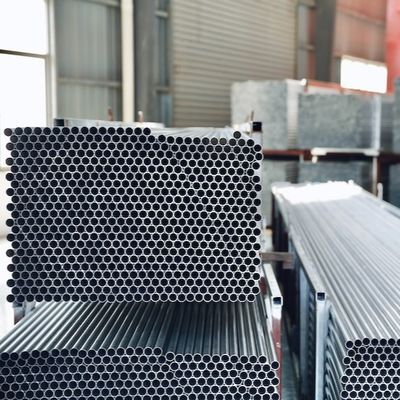

1050 D26 Aluminum Coil Pipe Anticorrosive Aluminum Coiled Power Plant Cooling Water Tower

| Place of Origin | From Jiangsu, China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 1050 |

| Minimum Order Quantity | 3 tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Aluminum Coil Tubing | Application | Power Plant Water Cooling Tower, Surface Condenser,Air-conditioner, Refrigerator |

|---|---|---|---|

| Material | Aluminum Or Aluminum Alloy | Color | Silver |

| Tensile Strength /MPa | 100-135 | Non-proportional Elongation Strength | ≥ 80Mpa |

| Elongation After Break | A50mm ≥ 5% | Outside Diameter | 26mm |

| Wall Thickness/mm | 0.8mm | Length | 5000mm |

| Maximum Length | 18 Meters | Specification | According To The National Standards Or According To Customer Special Requirements For Customization |

| High Light | 1050 D26 aluminum coil pipe,aluminum coil pipe Anticorrosive,water cooling metal tubing 135MPa |

||

Aluminum 1050 D26 Anticorrosive Aluminum Coiled Power Plant Cooling Water Tower

Product Description:

Our company can produce 15mm ~ 30mm outside diameter, wall thickness 0.8 mm ~ 2.0 mm, length 3M ~ 15m air-cooled island tube (aluminum heat exchanger tube) . Can also be customized according to customer needs non-standard specifications of the heat exchange equipment aluminum tube.

The product is made of aluminum alloy. The final state of the product is: straight tube. We passivate and anticorrosion the inner and outer surfaces of aluminum tube, and add anticorrosive coating on the inner and outer surfaces, which is suitable for the use of large heat exchanger.

The company is committed to the global refrigeration and heating and new energy fields to provide high-precision high-corrosion aluminum-based new materials and components. The company has advanced automatic production equipment, we have the leading compound molding production line, complete hot extrusion, compound molding, drawing, drawing, heat treatment, straightening cut-off, wound detection and other production equipment and advanced testing equipment. With an annual output of more than 10,000 tons of various specifications of high-performance high-reliability heat exchange aluminum tube production capacity.

Features:

Aluminum alloys are widely used in aircraft, automobiles and rockets because of their light weight and high strength. Due to its good electrical and thermal conductivity, aluminum can be used as a voltage cable material. High purity aluminum has better performance. The reducibility of aluminum at high temperatures can be used to smelt metals with high melting points. (this method of smelting metals is called the"Thermite process.") Aluminum is abundant and can be made into aluminum foil for packaging. Aluminum corrosion resistance (especially oxidation, because its oxide aluminum oxide instead increased the corrosion resistance and heat resistance of aluminum) excellent, good appearance and texture.

1 series aluminum alloy is suitable for automobile heat exchange system, power plant cooling industry, automobile water tank, electric hardware, air-cooled heat exchange industry, optical instrument, fire equipment and other industries. Aluminum has a wide range of uses because of its many excellent properties.

Our company is equipped with advanced automatic production equipment and testing equipment, its unique compound molding process production line, strong technical force, testing equipment, widely used in refrigeration, heating and new energy and other fields.

Applications:

Power plant water cooling tower

surface condenser

Large heat exchange equipment

condensator

evaporimeter

etc.

Technical Parameters:

Aluminum Coil Tubing

| (Main Size) | State | Outside Diameter /mm | Wall Thickness /mm | Length /m | Tensile Strength /MPa | Non-proportional Elongation Strength /MPa | Elongation After Break A50/mm | ||

| Model Number | |||||||||

| Main Size | |||||||||

| Series 1 | 1050 1060 1070 1050A | O | 20-32 | 0.8-2.0 | 5-15 | ≤20.00 | 60~95 | ≥70 | ≥25.00 |

| H14 | ≤10.00 | 100~135 | ≥70 | ≥5.00 | |||||

| Series 3 | 3003 3103 3A21 | O | ≤20.00 | 95~130 | ≥35 | ≥25.00 | |||

| H12 | ≤15.00 | 115~150 | ≥75 | ≥12.00 | |||||

| H14,H24 | ≤10.00 | 135~165 | ≥110 | ≥6.00 | |||||

| H28 | ≤3.00 | ≥180 | ≥145 | ≥3.00 | |||||

Support and Services:

We can provide technical support and services for the use of aluminum pipes, including technical guidance, production assistance, etc. Our experienced technicians can assist you with any problems your product may encounter. We also provide regular after-sales service to ensure that your products are always run at the highest efficiency. We are proud of our work and strive to provide the best customer service.

If you have any questions or concerns about the product or your use, please feel free to contact us. We will always give you the answers you need.

FAQ:

Q1: What kind of material alloy is the product?

A1: At present, it can produce 1 series industrial aluminum alloy, 3003 and 3103 aluminum manganese alloy, and 6 series aluminum alloy.

Q2: What state and performance of the aluminum pipe can be produced?

A2: can produce from hard state to soft state and interval performance products

Q3: Can I customize the product specifications and requirements?

A3: Different materials and products with different requirements can be customized according to the requirements

Q 4: What is the minimum starting order volume?

A 4: The minimum order volume is 3 tons.