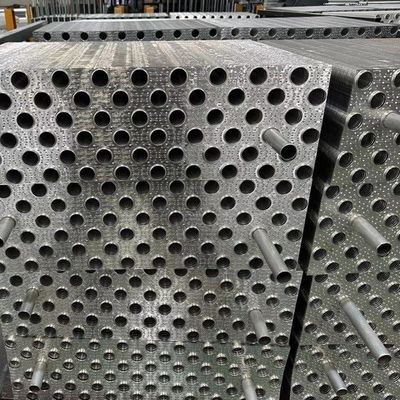

High Heat Transfer Performance Condensing Louvers Specification 21*21.65mm Anticorrosive Aluminum

| Place of Origin | Jiangsu China |

|---|---|

| Brand Name | YUN NENG |

| Certification | SO9001 ISO14001 ISO45001 |

| Model Number | FA8X16 |

| Minimum Order Quantity | negotiation |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | negotiation |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminum | Fin Type | Louvered (frond And Rear) |

|---|---|---|---|

| Fin Mold | Φ7.94 | Pattern/mm | 21*21.65 |

| Available Fin Type | Louver,Raised Lance,Lance,Flat | Specification | According To The National Standards Or According To Customer Special Requirements For Customization |

| High Light | Heat Transfer aircon louvres,aircon louvres Anticorrosive,Aluminum louvered fin |

||

High Heat Transfer Performance Condensing Louvers Specification 21*21.65mm Anticorrosive Aluminum

Product description:

The function of the window fin

The fins provide the additional surface area needed to efficiently transfer heat from the fluid tube side to the gas on the fin side. It plays a vital role in the heat exchanger itself.

Finned radiator is one of the most widely used heat exchangers in gas and liquid heat exchangers. It can enhance heat transfer by adding fins on the common tube.

All finned enhancement concepts improve heat transfer performance through air turbulence and increased surface area, and their effectiveness may differ in some important considerations.

The Finned-tube heat exchanger spacing and fin height mainly affect the fin-to-fin ratio, the fin-to-tube ratio and the film heat transfer coefficient of the media inside and outside the tube has a great relationship. If there is a big difference in the heat transfer coefficient between the inner and outer membrane of the tube, the finned tube with a larger winged ratio, such as steam heating air, should be selected. When there is a phase change on one side of the medium, the difference of heat transfer coefficient will be larger, such as the exchange of hot and cold air, when the hot air down to the dew point below, you can use finned tube heat exchanger. In the case of heat transfer between air and air without phase change, or between water and water, bare pipes are usually preferred. Of course, low-finned tube can also be used, because at this time belongs to the weak heat transfer coefficient, strengthening one of either side is a certain effect. However, the effect of excessive wing ratio is not obvious, the best contact area of both inside and outside the tube at the same time strengthen, can be used threaded or grooved tube.

Features:

Common design of Louvered fin

The fin constitutes the elementary heat transfer component, designed to enlarge the heat transfer surface area and enhance the efficiency of heat transfer.

Common Louvre fins possess notches directed in the same way, which are intended to augment air turbulence in a single direction.

As the angles of the louvres’ severity increase, their heat transfer performance improves until reaching a particular point, beyond which their efficiency starts to decline.

One noteworthy aspect of louvered fins is their directional nature which must be taken into consideration. Similar to shark skin, where contact in one direction is smooth and the opposite direction is coarse and sharp, the orientation of the louvers needs to be accurate as improper directionality can impair performance instead of enhancing it.

Heat transfer: Excellent

Fouling/clean ability: Poor

Durability: Moderate

Original louver fins

The original louver fins have different fin types to adapt to different heat transfer. It also allows for simplified geometry and enhanced heat dissipation and minimum pressure drop.

Yun Neng Group company:

Dedicated to the global refrigeration and heating and new energy fields to provide high-precision high-corrosion aluminum-based new materials and components. The company always adhere to scientific and technological innovation, deep cultivation of industrial cutting-edge technology, and strive to industry customers and partners continue to enable, win-win.

Techical Parameters :

Tube-fin type air conditioning condenser and evaporator Specifications

| Fin mold | Pattern/mm | Fin type | |||

| Φ7 | 21*12.7 | Louver | Raised lance | Lance | Flat |

| Φ7 | 21*18.19 | louver | Raised lance | Lance | V-wave |

| Φ7.94 |

21*21.65

|

louver on waffle | V-wave | ||

| Φ10.2 |

20*15.5

|

Turbolator

|

|||

| Φ12.3 |

25*21.65

|

Turbolator

|

|||

| Φ12.3 |

32*27.71

|

Turbolator

|

|||

| Φ14.3 | 34*29.5 |

Turbolator

|

|||

| Φ14.3 | 34*29.5 | Raised lance | |||

| Φ25.45 | 64*32 | Upper&lower lance | |||

| Φ25.5 | 66.6*32.25 | Raised lance | |||

| Φ9.52 | 25*21.65 | Louver | |||

Support and Services:

Fin, micro-channel cooling tube and collector tube can be customized according to customer's special requirements, product width can be customized, length and direction can be arbitrarily adjusted to meet different application scenarios.

FAQ:

Q1: What kind of material alloy is the product?

A1: At present, it can produce 1 series industrial aluminum alloy, 3003 and 3103 aluminum manganese alloy, and 6 series aluminum alloy.

Q2: What state and performance of the aluminum pipe can be produced?

A2: can produce from hard state to soft state and interval performance products

Q3: Can I customize the product specifications and requirements?

A3: Different materials and products with different requirements can be customized according to the requirements

Q 4: What is the minimum starting order volume?

A 4: The minimum order volume is 3 tons.