FMC FME Micro Channel Condenser Reliable Aluminium Corrosion Resistance Of Aluminum 0395

| Place of Origin | Jiangsu China |

|---|---|

| Brand Name | Yun Neng |

| Certification | SO9001 ISO14001 ISO45001 |

| Model Number | 3102/9153 |

| Minimum Order Quantity | negotiation |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | negotiation |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminum Alloy | Model Name | Manufacturing Materials-Header |

|---|---|---|---|

| State | H112 | Model Number | 0395 |

| Tensile Strength/mp | 280-240 | Yield Strength/mp | 150 |

| High Light | FMC Micro Channel Condenser,FME Micro Channel Condenser,aluminum alloy tube 0395 |

||

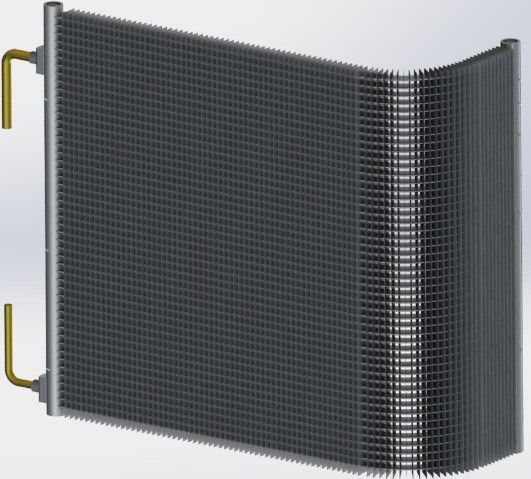

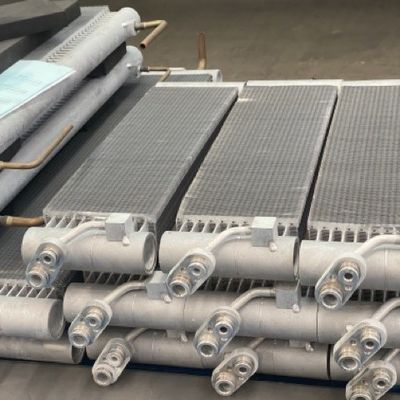

FMC/FME Micro-Channel Condenser Reliable Aluminium Corrosion Resistance Of Aluminum 0395

Product description:

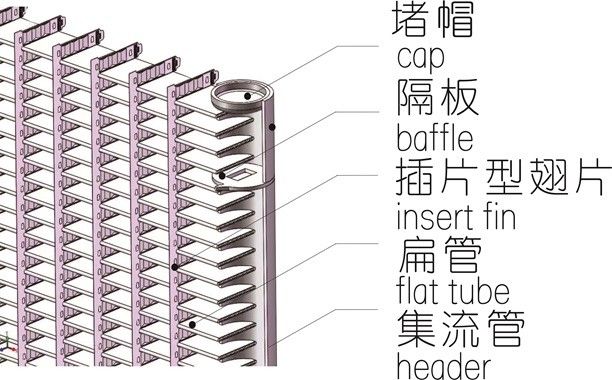

FMC/FME is a new type of micro-channel heat exchanger developed to address the problems of condensation and frost melting water that are difficult to discharge from conventional single-cooling parallel flow (PFC), as well as the uneven distribution of the refrigerant gas-liquid two-phase, which is unable to meet the problem of heat pump air conditioners with both condensation and evaporation functions.

Multiple refrigerant distribution programme

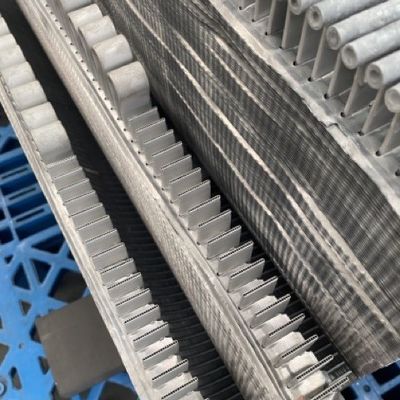

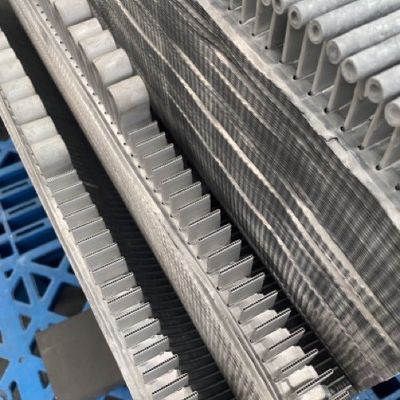

Each zone arranges a different number of porous flat tubes in parallel in the direction of gravity based on the state of the refrigerant in the two-phase and the demand of heat exchange. The header tubes at both ends and the partition plate in the middle divide the porous flat tube into multiple zones. The refrigerant flows back and forth in each zone to form a condensation/evaporation circuit.

The design of the refrigerant distribution program takes into account the different needs and characteristics of the system.

Features:

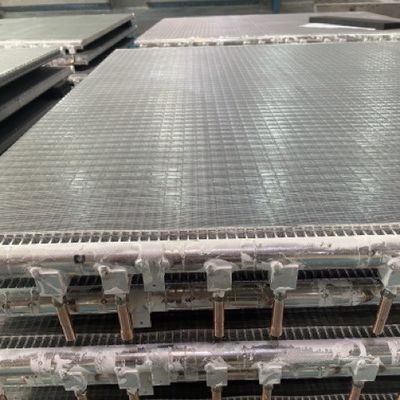

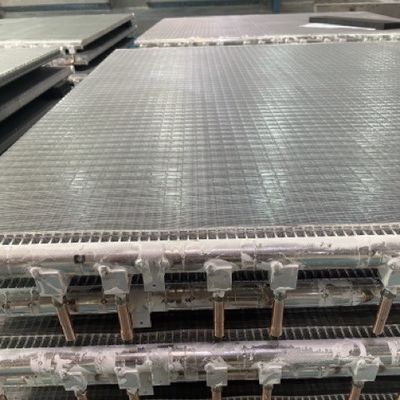

Reliability

Products for the entire aluminium alloy, compared with copper tube aluminium fin heat exchanger material between the potential difference is small, potential corrosion is small, but aluminium resistance to environmental corrosion is poorer than copper, so in order to comply with the use of air-conditioning products cycle, through the different aluminium alloys (porous micro-channel tubes, aluminium fins, the header tubes)

The combination of passivation and hydrophilic coating improves the overall corrosion resistance of aluminum alloy materials.

Application of refrigerant and cost savings

Can be used with a variety of refrigerants; high-pressure refrigerant tube small micro-channel considerably decreases tube volume, allowing for refrigerant savings.

Techical Parameters:

Manufacturing materials-Header

| Fin size | Pitch | Notch |

|

Φ25×1.5T

|

10.5/7.7

|

20×2.1/20×2

|

|

Φ32×1.8T

|

10.5

|

25.4×2

|

|

Φ38×2.2T

|

10.5

|

32×2

|

|

New Header1

|

10.5/7.7

|

20X2.1/20X2/25.4X2

|

|

New Header2

|

10.5/7.7

|

20x2.1/20x2/25.4x2

|

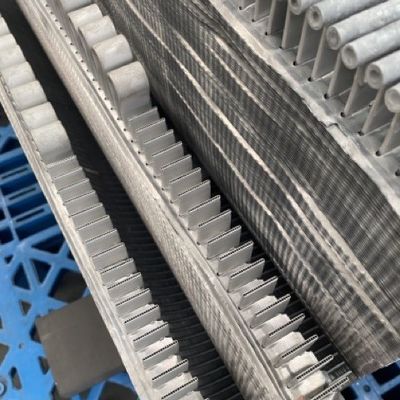

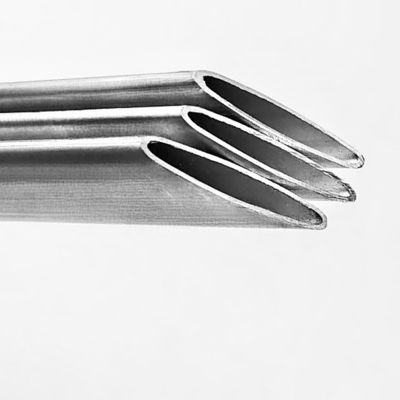

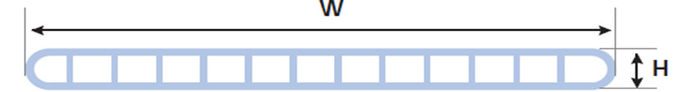

Manufacturing materials-Porous micro-channel tubes

| Height/mm | Width/mm | Number of holes |

| 2.1 | 20 | 16 |

| 2.0 | 25.4 | 26/20/13 |

| 2.0 | 32 | 32/13 |

| 2.0 | 20 | 16/15/12 |

Applications:

Household heat pump and air-conditioning condenser;

Commercial multi-line evaporator, condenser;

Commercial heat pump system (module machine) evaporator;

Bus and car air-conditioning evaporator, condenser;

Commercial air-conditioning duct machine evaporator;

Electric locomotive, rv, truck, engineering vehicle condensers, evaporator;

New energy vehicle air conditioning condenser, evaporator...

Etc.