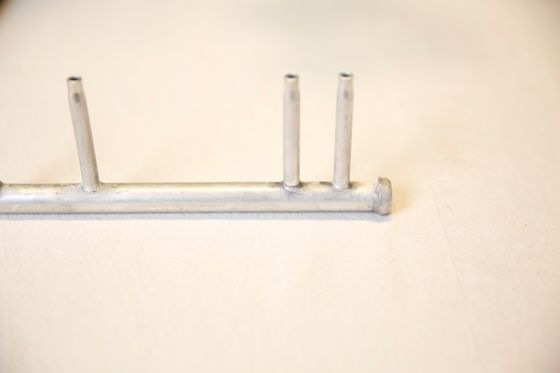

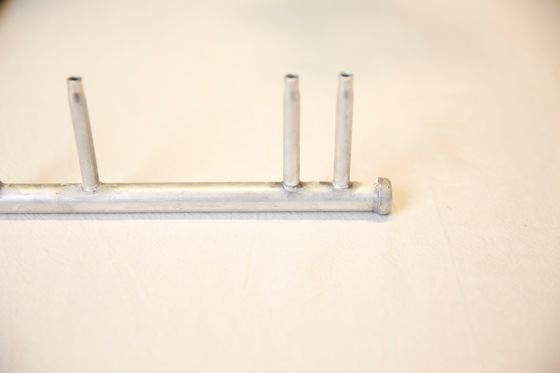

Air Conditioning Copper Aluminum Connection Pipe Durable Safe Efficient

| Place of Origin | Changzhou, China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 1060 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Air Conditioning Connection Pipe |

|---|---|---|---|

| Model Number | 1060 | State | M(O) |

| Outside Diameter/mm | 4-22 | Thickness/mm | 0.24-2.00 |

| Shape | Coil | Applications | Dehumidifier ,Cold Dry Machine, Warm Air Blower |

| High Light | Air Conditioning Copper Aluminum Connection Pipe,1060 Copper Aluminum Connection Pipe,AC Connection Pipe 0.24mm |

||

Copper-Aluminum Air-Conditioning Connection Pipe: Durable, Safe & Efficient

Detailed explanation of technical standards for copper-aluminum connecting pipes:

1. Quality requirements for welding points:

The welding joints of copper and aluminum connecting pipes must be free of defects such as pores, cracks, slag, burrs and burns. The two metals, copper and aluminum, should be completely fused during the welding process, with no obvious oxide film. In addition, the size of the plug hole should comply with the standard and cannot be significantly reduced. For example, for a Φ6.3 hole, the size should be greater than 3.0mm.

2. Air tightness requirements:

The air tightness requirements of copper-aluminum connecting pipes are very strict, and a high-pressure test of 4.0MPa is required for 5 minutes to determine whether the connecting pipes are leaking. This strict testing ensures the stability and reliability of the connecting pipe in high-pressure environments.

3. Pressure resistance performance requirements:

After passing the air tightness inspection, the pressure needs to be slowly increased to 13MPa and maintained for 1 minute to test the pressure resistance of the copper-aluminum connecting pipe. During this process, the copper-aluminum connecting pipe cannot have any cracks to ensure its stability in high-pressure environments.

4. Bending performance requirements:

The bending performance requirements of copper-aluminum connecting pipes are very high. The sample needs to be bent into a bending core that is twice the nominal diameter of the pipe, and then inspected after bending 180 degrees. Pipes should be free of wrinkles and cracks to ensure their stability and reliability under bending.

5. Tensile strength requirements:

The tensile strength requirement of copper-aluminum connecting pipe is between 65-118mpa. In the tensile test, the tensile part should be on the side of the aluminum pipe, and the length of the weld should be more than 10mm. This ensures the stability and reliability of the connecting pipe when subjected to tension.

6. Sealing performance requirements:

The sealing performance requirements of copper-aluminum connecting pipes are very high. The KTG shrinkage should be good and the sealing fittings have been melted and completely wrapped in the copper-aluminum joint. In the sealed state, the seal cannot rotate to ensure the sealing and stability of the connecting pipe.

Features:

The copper-aluminum air-conditioning connecting pipe is an innovative air-conditioning connecting pipe. It is composed of a section of copper pipe and a section of aluminum pipe tightly combined through advanced welding technology. This unique combination gives the copper-aluminum air conditioning connecting pipe a series of outstanding features and advantages.

First of all, the copper pipe part of the copper-aluminum connecting pipe can be perfectly connected with the brass parts of the air conditioner's internal and external units, ensuring the stability and durability of the connection. In addition, due to the high chemical stability of copper, the risk of electrochemical corrosion between aluminum tubes and brass parts can be effectively avoided. In this way, users can use this connecting pipe with more confidence without worrying about leakage or damage, thereby improving the durability and safety of the connecting pipe.

Secondly, the aluminum pipe part of the copper-aluminum connecting pipe has the advantage of reducing the weight and cost of the connecting pipe. Aluminum is a lightweight, high-strength metal material. Compared with traditional pure copper connecting pipes, copper-aluminum connecting pipes are significantly lighter in weight, making installation and transportation easier. In addition, the cost of aluminum pipes is also low, which allows the manufacturing cost of copper-aluminum air conditioning connecting pipes to be effectively controlled, saving unnecessary expenses for users.

More importantly, the environmental impact of copper-aluminum connecting pipes is also reduced. Aluminum is a renewable metal material. Through reasonable recycling and reuse, effective recycling of resources can be achieved. Compared with traditional pure copper connecting pipes, copper-aluminum connecting pipes have a higher recycling rate and will not cause resource shortages and environmental damage. This is in line with the current society's pursuit of sustainable development and provides users with a more environmentally friendly air conditioning connecting pipe solution.

Finally, the overall thermal insulation performance of copper-aluminum air conditioning connecting pipes is better than that of pure aluminum pipes. Due to the low thermal conductivity of the copper tube, it can effectively prevent the transfer of heat and keep the internal temperature of the connecting tube stable. In this way, the loss of refrigerant during the transportation process is reduced, and the cooling and heating efficiency of the air conditioner is improved. At the same time, this also means that the use of this connecting pipe can reduce energy consumption and carbon emissions, making a positive contribution to environmental protection.

To sum up, the copper-aluminum air conditioning connecting pipe combines excellent performance, environmental protection and economic advantages with its innovative design and technology. It provides users with an efficient, safe and environmentally friendly air conditioning connecting pipe solution, adapting to the needs of modern society for sustainable development.

Applications:

evaporimeter

condensator

dehumidifier

Cold dry machine

warm air blower

etc.

Techical Parameters:

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/m m | ||

| 1050,1060,1070 | M(O) | 4-22 | 0.24-2.00 |

| H14 | |||

| 3003,3103 | M(O) | ||

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Support and Services:

We can provide technical support and services for the use of aluminum pipes, including technical guidance, assistance in production, etc. Our experienced technicians can assist you with any problems your product may encounter. We also provide regular after-sales service to ensure that your products are always run at the highest efficiency. We are proud of our work and strive to provide the best customer service.

If you have any questions or concerns about the product or your use, please feel free to contact us. We will always give you the answers you need.

FAQ.:

Q1: aluminum alloy pipe compared with copper pipe, advantages and disadvantages?

A1: Aluminum pipe cost low ductility, but easy to corrosion. Copper pipes have good thermal conductivity and corrosion resistance, but the installation, preservation and transportation are not easy and the cost is high.

Q2: What should be noted in the installation of the air conditioning connection pipe?

A2: The alloy pipe is easy to install, but the link of copper and aluminum after a long time of chemical changes, will cause electrocouple corrosion.

Q3: How to deal with the corrosion problem?

A3: Our products use special corrosion resistant alloy, and the corrosion resistance effect is greatly improved compared with ordinary aluminum alloy. The corrosion resistance experiment is> 1000 hours, which greatly improves the service life of the product.

Q 4: What state and performance of aluminum pipe and aluminum alloy pipe can be produced?

A 4: It can produce performance products from hard state to soft state and interval.