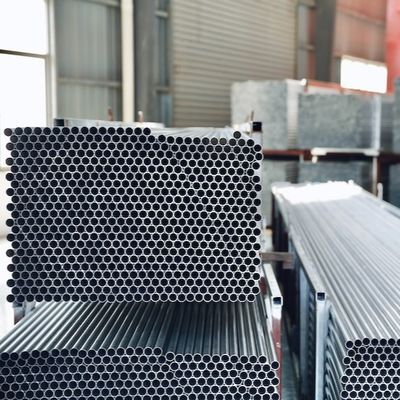

12mm Radiator Extruded Aluminum Tube Cold Drawn Tube 3103 H14

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3103 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3103 | State | H14 |

| Shape | Round | Outside Diameter/mm | 12 |

| Thickness/mm | 0.9 | ||

| High Light | 12mm Cold Drawn Aluminium Tube,Radiator Extruded Aluminum Tube,Cold Drawn Tube 3103 H14 |

||

Brand 3103 H14 12mm Radiator Extruded Aluminum Tube Cold-drawn Tube

What does "aluminum extruded" mean exactly?

Extrusion, which is the use of a specific medium, such as aluminum or other materials, through the die longitudinal cutting to form a cross-section of the bar process. Although the steps are a bit cumbersome, but in fact the whole operation is very simple! Before getting the ideal final shape of the extrusion rod, the manufacturer or designer needs to design and manufacture the die with the best matching.

Cold finished aluminum, in layman's terms, what exactly is it?

Extrusion or die-casting is usually carried out at high temperature in order to better precipitate aluminum, while the cooling process only needs to be carried out at room temperature.

The unique outside diameter precision control is realized in the cold treatment stage.

One of the more common cold working techniques is stretching.

When making aluminum bars, the drawing die is used to reduce the material diameter.

A small-diameter metal rod section is filled into the drawing die, and then the drawing operation is carried out through the rod section. Although drawing patterns can be done at high temperatures, it is not a mainstream practice.

The result of cold treatment is determined by the deformation and extension of aluminum. In the process of restoration, aluminum has undergone artificial strengthening, thus changing the original mechanical and physical properties, and thus improve the bar surface smoothness.

Features:

The difference lies in the extrusion of aluminum and cold processing of aluminum production process is different. The advantage of standard aluminum profiles is that they are easier to use at high temperatures, while extruders are relatively inexpensive and have shorter lead times due to increased production efficiency.

The reduction process involved in cold finished production produces tighter dimensional tolerances, a benefit when using the close-fitting collets in today’s high-speed precision CNC machining centers. It also elevates the mechanical and physical properties of the material; this increases the machinability and produces smaller chips during machining that break away from the cutting tool’s work area faster.

There is a long list of benefits for aluminum bar that are shared by both products.

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Applications:

While extruded aluminum is extremely common in a wide range of applications, it is not suitable for everything. Any requirement for elevated properties may turn toward cold finished product as raw material. Aerospace and defense products requiring high strength often specify cold finished bar, as well as a host of automotive applications.