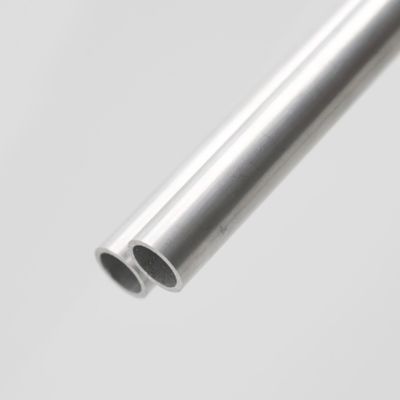

Extruded Cold Drawn Aluminium Tube 3003 H14 14mm For Radiator

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3103 | State | H14 |

| Shape | Round | Outside Diameter/mm | 14 |

| Thickness/mm | 1.3 | ||

| High Light | Cold Drawn Aluminium Tube 14mm,Cold Drawn Aluminium Tube 3003 H14,Extruded Round Aluminum Pipe |

||

3003 H14 Cold Drawn Aluminum Alloy Tubing For Radiator Extruded Aluminum Tube

1, Overview

Aluminum tube cold drawing process is a processing method of cold drawing prepared aluminum rods according to certain process requirements. By gradually compressing the cross-sectional shape of the aluminum rod through multiple drawing processes, the surface quality and dimensional accuracy have been significantly improved. This process is suitable for producing high demand aluminum alloy pipes and is widely used in industries such as aviation, automotive, rail transit, and electronics.

2, Process

The basic process of aluminum tube cold drawing process includes a series of steps such as bar material selection, pre-treatment, initial drawing, drying, intermediate drawing, heat treatment, final drawing, straightening, pickling, and cold treatment. The initial drawing process involves placing the aluminum rod on a machining machine for preliminary stretching processing, promoting the deformation of the bar material. Middle drawing is the process of pulling a bar in the middle to achieve the optimal external dimensions for manufacturing aluminum pipes. The function of final drawing is to eliminate burrs on the aluminum tube, further improving the surface quality and dimensional accuracy of the aluminum tube.

3, Characteristics

The aluminum tube cold drawing process has the following characteristics:

1. High precision: Cold drawing of aluminum tubes can improve the surface flatness of aluminum alloy tubes to below 0.02mm, and the dimensional accuracy can also reach about 0.05mm;

2. It can produce various complex shapes of aluminum tubes: The cold drawing process of aluminum tubes can process various complex tube shapes, such as irregular tubes, thin-walled tubes, etc;

3. Less burrs: The cold drawing process of aluminum tubes can effectively reduce burrs on the surface of the tubes and improve their surface quality.

4, Application

Aluminum tube cold drawing process is a major processing method for manufacturing high-precision and high demand aluminum alloy pipes, widely used in the following fields:

1. Aerospace field: production of high-speed transportation vehicles such as airplanes and rockets;

2. Transportation field: application of aluminum alloy materials such as automobiles, trains, subways, etc;

3. Electronics field: packaging of electronic products, production of conductive tubes, etc.

【 Conclusion 】

The cold drawing process of aluminum tubes is an important method for manufacturing high-precision aluminum tubes, characterized by high surface smoothness, high dimensional accuracy, and few burrs of the processed aluminum tubes; Applied in industries such as aviation, automotive, rail transit, and electronics, it has broad market prospects.

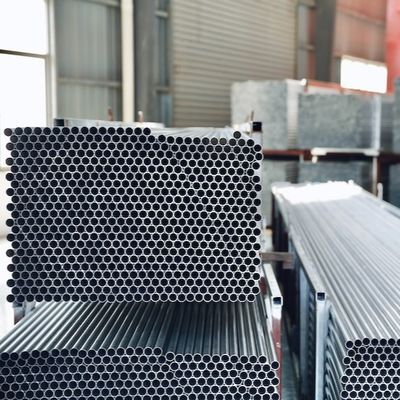

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Applications:

While extruded aluminum is extremely common in a wide range of applications, it is not suitable for everything. Any requirement for elevated properties may turn toward cold finished product as raw material. Aerospace and defense products requiring high strength often specify cold finished bar, as well as a host of automotive applications.