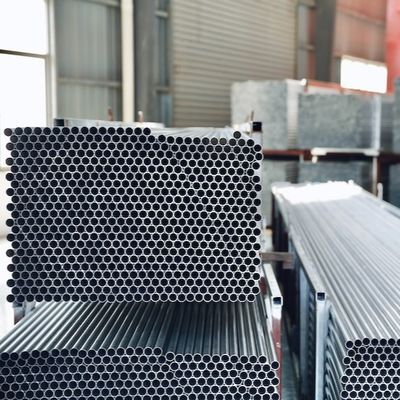

3003 H12 Radiator Cold Drawn Tube Extruding Aluminum Tube Outside Diameter 5 Mm

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3003 | State | H12 |

| Shape | Round | Outside Diameter/mm | 5 |

| Thickness/mm | 0.3 | ||

| High Light | Radiator Cold Drawn Aluminium Pipe,3003 H12 Extruding Aluminum Tube,Extruding Aluminum Cold Drawn Tube |

||

3003 H12 Outside Diameter 5 mm Radiator Cold-drawn Tube Extruding Aluminum Tube

Product Description:

3003:

with the performance of 1 series alloys and to have a higher strength than 1 series alloys, such as kitchenware, food and chemical product handling and storage devices, transportation of liquid products tanks, tanks, as well as thin plate processing of a variety of pressure vessels and piping.

H12:

H hardening state:

It is suitable for products whose strength is improved by work-hardening, and the products may or may not be subjected to additional heat treatment after work-hardening to reduce the strength.

The first digit after H indicates the method of work-hardening treatment.

H12:Work hardening to 25% hardness

Features:

By means of precision NC machine tool with compact Chuck, we have successfully realized the efficient optimization of cold working process. This unique method not only effectively improves the product accuracy, but also helps to improve the mechanical and physical properties of materials, thus improving the machining efficiency and making the cutting process more detailed and faster. In addition, this advantage is also reflected in the smooth operation of the tool. Undoubtedly, this will be a significant competitive advantage for our products.

We can provide technical support and services for the use of aluminum pipes, including technical guidance, production assistance, etc. Our experienced technicians can assist you with any problems your product may encounter. We also provide regular after-sales service to ensure that your products are always run at the highest efficiency. We are proud of our work and strive to provide the best customer service.

If you have any questions or concerns about the product or your use, please feel free to contact us. We will always give you the answers you need.

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Applications:

While extruded aluminum is extremely common in a wide range of applications, it is not suitable for everything. Any requirement for elevated properties may turn toward cold finished product as raw material. Aerospace and defense products requiring high strength often specify cold finished bar, as well as a host of automotive applications.

Support and Services:

We can provide technical support and services for the use of thread aluminum pipes, including the production of the opening, bending, pipe raising, welding and other rear process technical guidance, assistance in production, etc. Our experienced technicians can assist you with any problems your product may encounter. We also provide regular after-sales service to ensure that your products are always run at the highest efficiency. We are proud of our work and strive to provide the best customer service.

If you have any questions or concerns about the product or your use, please feel free to contact us.