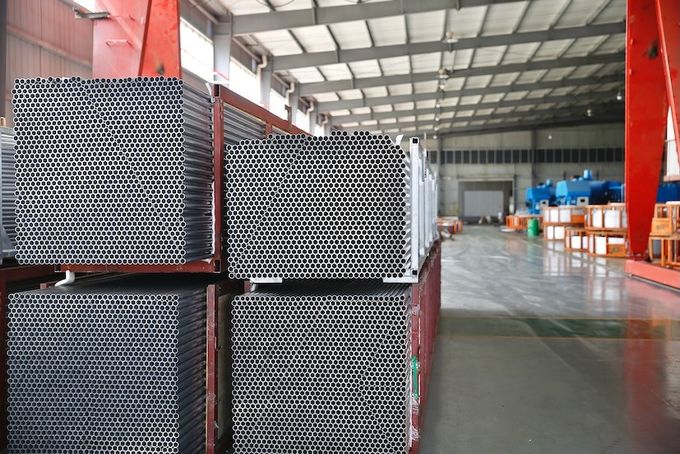

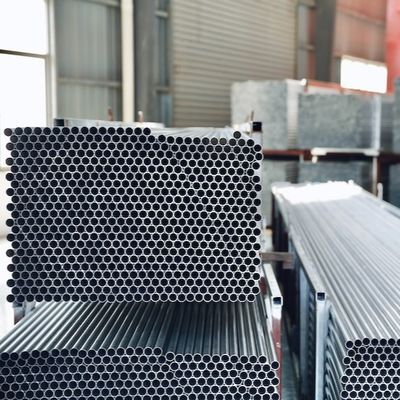

3103 H14 Cold Drawn Extruded Aluminum Tube 12mm Radiator Uses

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3103 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3103 | State | H14 |

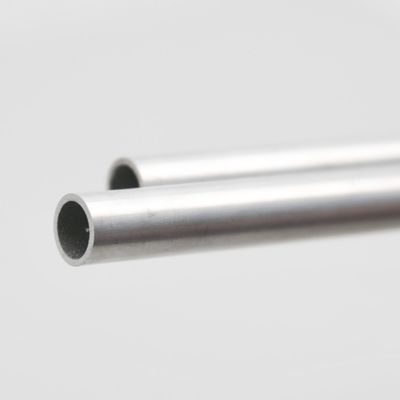

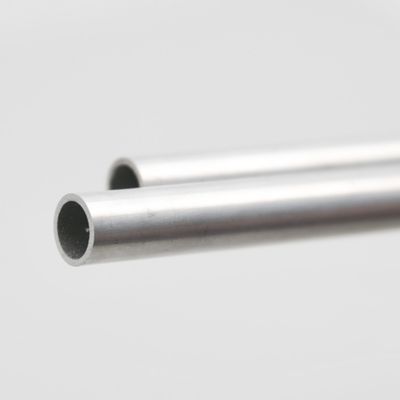

| Shape | Round | Outside Diameter/mm | 12 |

| Thickness/mm | 0.3 | ||

| High Light | Extruded Cold Drawn Aluminum Pipe,Radiator Cold Drawn Aluminum Tube 12mm,3103 H14 Extruded Aluminum Tube |

||

The Radiator Uses 3103 H14 12mm Cold-drawn Extruded Aluminum Tube

1, Overview

The Aluminum Tube Cold Drawing Process: A Key for Enhancing the Quality and Dimensional Precision of Aluminum Alloy Tubes.

The aluminum tube cold drawing process is an artfully crafted method for fabricating aluminum rods based on specific technological stipulations. Through successive cold drawing processes, the cross-sectional shape of the aluminum rod is meticulously compressed, significantly enhancing the surface quality and dimensional precision of the rod. This acclaimed process is ideal for producing high demand aluminum alloy tubes and is widely utilized in sectors such as aviation, automotive, rail transit, electronics, etc.

2, Process

The Fundamental Process of Cold Drawing in Aluminum Tube Manufacturing.

The fundamental procedure of cold drawing technology for aluminum tubes encompasses a series of steps including the selection of rodstock, pre-treatment, initial drawing, drying, intermediate drawing, heat treatment, ultimate drawing, straightening, pickling and cold treatment. The process of the initial drawing includes setting the aluminum rod on the machine tool for primary drawing work to induce deformation in the rodstock. The function of the intermediate drawing is to draw a steel bar in the middle to achieve the optimum shape dimension for the manufacture of the aluminum tube. The purpose of the final deep drawing is to eliminate burrs on the aluminum tube, further improve the surface quality and dimensional precision of the aluminum tube.

3, Characteristics

The cold extrusion process of aluminium tubing boasts the following advantageous characteristics:

1. Stainless Steel Tube delivers superior cold drawing precision, Cold drawing of the aluminum alloy tube can elevate its surface flatness to below 0.02 millimeters, and the dimension accuracy can also reach about 0.05 millimeters;

2. Aluminum Tube's Cold Drawing Process Crafts Varied Complex Shapes,The cold drawn process involved in the production of aluminum tubes allows us to fabricate various complex shapes, such as irregular tubes and thin walled tubes.

3.Enhancing Surface Quality and Minimizing Burrs via the Aluminum Tube Cold Drawing Process,The cold drawing process for aluminum tubing greatly reduces burrs on the tube surface, enhancing the tube's aesthetic quality.

4, Application

Aluminum tube cold drawing is the indispensable process employed to fabricate high precision, elevated guise aluminum alloy tubes, and it has broad applications in these sectors:

1. Aerospace domain: The production of aircrafts, rockets, and other high- velocity transportation vehicles;

2. Transport sector: the utilization of aluminum alloy materials in cars, trains, subways, etc.;

3. Electronic field: electronic product packaging, and the production of conductive pipes, etc.

【 Conclusion 】

The Advantages and Market Prospects of the Aluminum Tube Cold Drawing Process: Cold drawing process of aluminum tube is an essential method for fabricating high-precision aluminum tubes. This process demonstrates high attributes, superior surface smoothness, precise size precision and minimal machining burr of aluminum tubes, rendering it advantageous in diverse industries such as aviation, automotive, rail transit, electronics, and so forth.

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Applications:

While extruded aluminum is extremely common in a wide range of applications, it is not suitable for everything. Any requirement for elevated properties may turn toward cold finished product as raw material. Aerospace and defense products requiring high strength often specify cold finished bar, as well as a host of automotive applications.