3103 15mm Round Aluminum Tube Corrosion Resistant For Automotive Radiator

| Place of Origin | Changzhou, China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3103 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

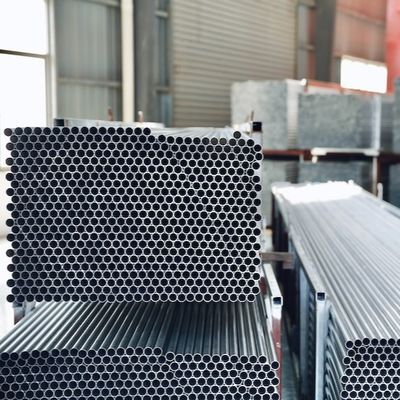

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Radiator Aluminum Alloy Tubing |

|---|---|---|---|

| Model Number | 3103 | State | H12 |

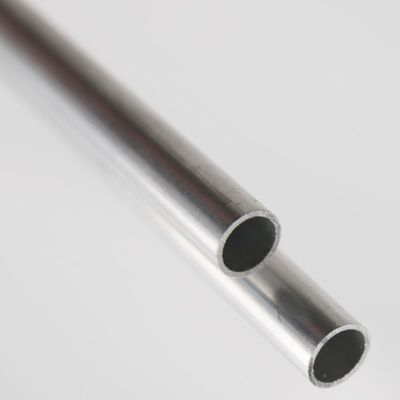

| Shape | Round | Outside Diameter/mm | 15 |

| Thickness/mm | 1.5 | ||

| High Light | Corrosion Resistant 3103 Aluminum Pipe,15mm Round Aluminum Tube,3103 Round Aluminum Tube |

||

3103 Outside Diameter 15 All-aluminum Corrosion-resistant Automotive Radiator Round Aluminum Tube

Product description:

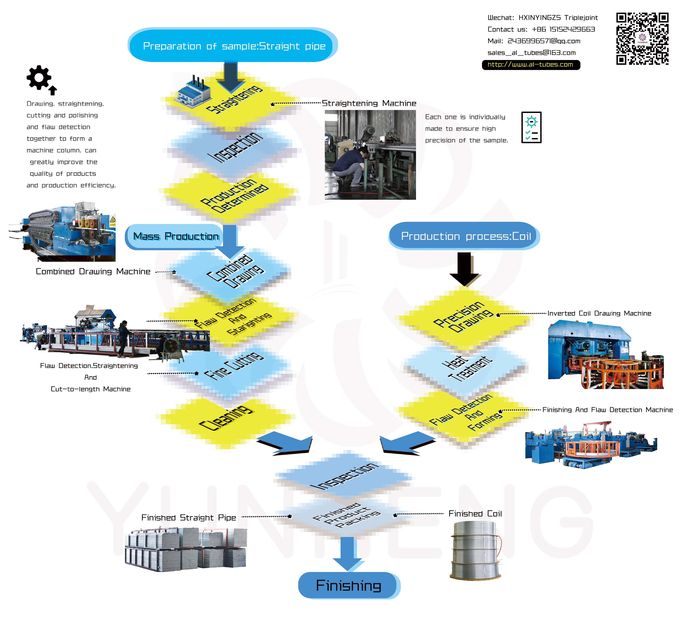

Aluminium alloy tubing boasts exceptional strength and durability against corrosion.Our 3003 and 3103 anti-rust aluminum compose our auto water tank pipes. These durable tubes are produced from top-shelf aluminum alloy. The raw material, remelted into high-grade aluminum bars, undergoes precise extrusion by a heavy-duty extruder. This ensures a consistent texture and impressive anti-rust, abrasion-resistance and pressure integrity.

Crafted with expertise, our anti-rust aluminium pipe undergoes advanced processes like hot extrusion and cold drawing for top-notch dimensions, smooth finishes, and waterproof and airtight traits. Our expertly tailored fixed-diameter straight pipe caters precisely to customer requirements in a variety of MY 2M aluminum pipe options. These flexible tubes are simple to install and repair, serving well as rear tank expansion openings and expansion tubes.

Features:

Our company's 3003/3103 aluminum alloy round tube provides stellar performance as an essential part for automobiles - it efficiently manages heat absorbed by components and guarantees smooth engine operations. This product's superior quality offers high thermal conductivity, robust corrosion resistance, and effortless shaping, making it a favored choice for various automotive cooling systems - think: air conditioning ducts, heat exchangers and more.

3003/3103 aluminum alloy round tubes excel in several automotive cooling systems due to their exceptional precision, minimum leakage rate and superb heat dissipation. They efficiently radiate car engine warmth while ensuring top system efficiency. Their precise control and superior sealing capably sustain performance at elevated pressures.

Beyond impressive heat transfer, these tubes are also conveniently light weight, making handling easier and more versatile, minimizing spacial demands. With exceptional resistance to corrosion, they perform stably in diverse environments and can be used in various automotive water tanks such as aluminum-plastic and aluminum.

The advantages and promising market of cold drawing technology in aluminum pipes: Cold drawing is an essential method for manufacturing high precision aluminum pipes. It presents superior qualities like smooth surface, precise dimensions with minimal burrs, perfect for sectors such as aviation, cars, rail transport, and electronics.

Applications:

condensator

evaporimeter

air conditioner external unit

ice box

refrigerator

Small heat exchanger

frigistor

Cold dry machine

warm air blower

packaged air conditioner

Dry wet machine

etc.

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production.)