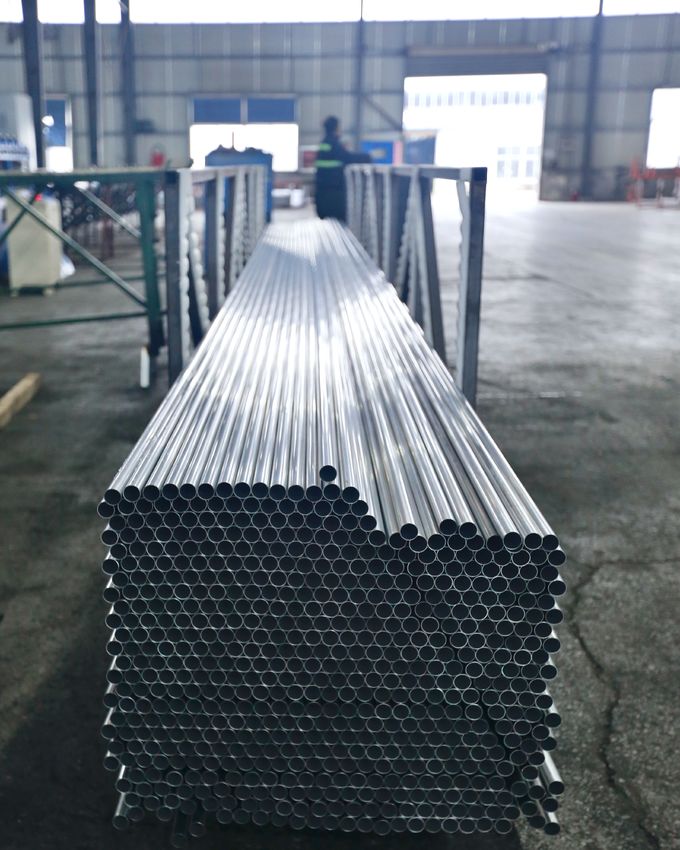

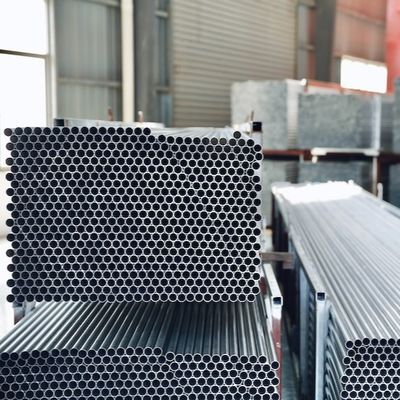

Aluminum 3103 H14 Radiator Cold Drawn Aluminium Tube Diameter 13.5 Mm

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3103 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3103 | State | H14 |

| Shape | Round | Outside Diameter/mm | 13.5 |

| Thickness/mm | 1.5 | ||

| High Light | Radiator Round Cold Drawn Tube,13.5 Mm Cold Drawn Aluminium Tube,3103 H14 Cold Drawn Aluminium Pipe |

||

Aluminum 3103 H14 Radiator Cold-drawn Aluminum Tube Diameter 13.5 mm

To accommodate specific technical specifications, our esteemed company often employs the sophisticated cold-drawn method to fabricate aluminum rods per industry standards. Through numerous rounds of drawing, the cross-sectional radius of the aluminum rod is progressively diminished, thereby enhancing product quality and precision. Given the current market's growing appetite for premium quality aluminum alloy pipes, this methodology proves highly flexible, having found application across a plethora of industries including aviation, automobiles, rail transit, electronics, among others.

The meticulous cold drawing procedure of aluminum tubes commences with selecting ideal raw materials and undertaking preliminary conditioning; it then progresses to initial extrusion morphing, followed by a critical drying phase, further evolving into intermediate stretching, dimension adjusting and heating pretreatments, before ultimately concluding with the final stretch aimed at rectifying defects, subsequent straightening, acidic cleansing, and an essential cold treatment to standardize the product. This preliminary phase involves delicately inserting the prepared aluminum rod into the equipment for precise deformation manipulation. Furthermore, in the intermediate stage, gradual steel withdrawal is executed to attain the desirous aluminum tube outside diameter. Lastly, the final stretch employs this methodology to eliminate any undesired burrs from the aluminum tube, thereby enhancing the accuracy and aesthetic appeal of the product.

Allow us to acquaint you with the exceptional attributes of cold-drawn aluminum tube.

Initially, its precision is unparalleled, enabling the aluminum alloy tube surface refinement to achieve a smoothness superior to 0.02 millimeters, and a dimensionality precision of approximately 0.05mm.

Subsequently, the production of an extensive range of intricate shapes poses no challenge; from asymmetrical or slim-walled tubes to any other potential formation, they are effortlessly accomplished through cold drawing technology. Lastly, this procedure significantly curbs burrs, enhancing the surface finish of the pipe.

Cold punching of aluminum tubing is extensively utilized in the creation of top-quality and demanding aluminum alloy pipe, particularly benefiting the following sectors: 1. Aerospace Sector: Guidance and construction of high-velocity vehicles such as aircrafts and rockets. 2. Transportation Universe: It serves vital roles in the production of motor vehicles, trains, and subways. 3. Electronic Manufacturing Arena: Appendixes like electronic product packaging and conductive tube creation.

Features:

In terms of reducing cold production, a stricter level of dimensional precision can be realized by utilizing high-precision CNC machine tools fitted with precise chucks. Additionally, this technique increases the material's mechanical and physical characteristics thereby enhancing its machining proficiency, facilitating a more refined cut and accelerating chip dissociation, ensuring the tool operates optimally. This represents an invaluable asset to our product line.

Our esteemed enterprise is furnished with sophisticated automated production apparatus and testing apparatuses, featuring our innovative compounded moulding procedure production line, robust technical prowess, comprehensive testing apparatus, which find extensive application across sectors such as refrigeration, heating, and innovative energy sources.

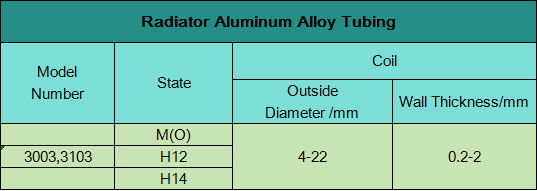

Techical Parameters:

(Technical requirements refer to national standards or customer technical quality requirements for production)

Applications:

While extruded aluminum is extremely common in a wide range of applications, it is not suitable for everything. Any requirement for elevated properties may turn toward cold finished product as raw material. Aerospace and defense products requiring high strength often specify cold finished bar, as well as a host of automotive applications.