Versatile Aluminium Alloys Tubing For Heat Exchanger Systems In The Oil And Gas Industry

| Place of Origin | Changzhou, China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 1050 |

| Minimum Order Quantity | 3 tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Length | 8000mm | Application | Air-conditioner, Refrigerator |

|---|---|---|---|

| Outside Diameter | 35mm | Size | Customized |

| Tensile Strength | 100MPa~135MPa | Wall Thickness | 1..8mm |

| Maximum Length | 15m | Non- Proportional Elongation Strength | ≥80MPa |

| Elongation After Break A50 | ≥5.00mm | Specification | According To The National Standards Or According To Customer Special Requirements For Customization |

| High Light | Heat Exchanger Systems Aluminium Alloys Tubing,Gas Industry Aluminium Alloys Tubing |

||

Versatile Aluminium Alloys for Heat Exchanger Systems in the Oil and Gas Industry

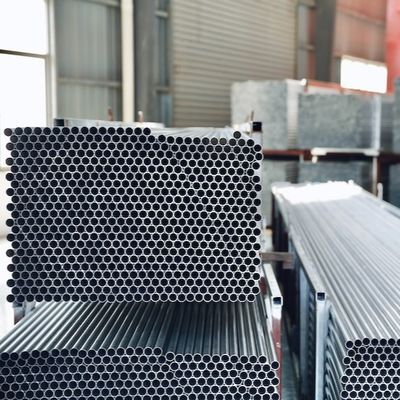

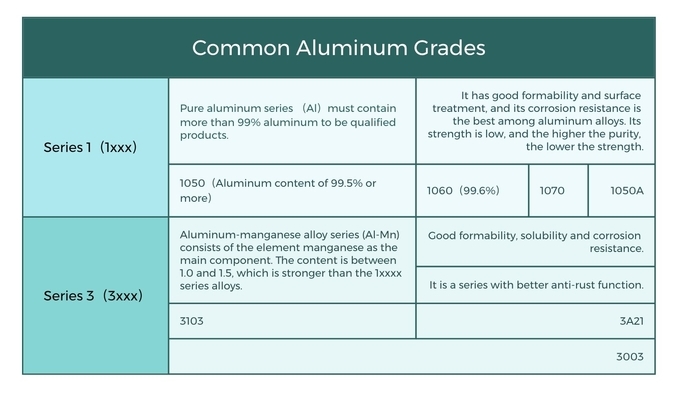

We proudly offer a range of pure aluminium tubes in the 1 series and corrosion-resistant aluminium tubes in the 3 series. Furthermore, we can cater to the unique requirements of our clients by customizing non-standard aluminium tubes suitable for heat exchanger equipment.

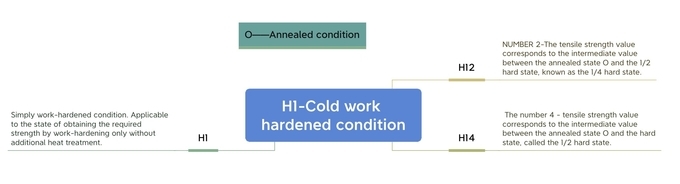

When it comes to processing aluminium alloys, we employ a diverse array of techniques, including heat treatment, cold treatment, solution heat treatment, aging treatment, and annealing treatment.

http://mao.ecer.com/test/al-tubes.com/cases/power-plant-air-cooling-tube-product-pamphlet-15462.html

Aluminium alloys stand out as one of the most versatile non-ferrous structural materials in the industry. Their low density, coupled with their remarkable strength- often matching or exceeding that of high-grade steel - makes them an ideal choice for a wide range of applications. These alloys exhibit excellent plasticity, allowing them to be easily shaped into diverse profiles. Additionally, their superior electrical and thermal conductivity, along with their corrosion resistance, ensures their widespread usage in various sectors such as aerospace, automotive, machinery manufacturing, shipbuilding, and the chemical industry.

Features:

We enhance the durability and resilience of aluminium tubes by applying passivation and corrosion-resistant treatments to both their internal and external surfaces. These surfaces are then coated with protective layers, tailored for use in extensive heat exchange systems.

The 1050 Aluminium alloy stands out for its superior formability, exquisite surface finish, and exceptional corrosion resistance - making it one of the most durable aluminium alloys available. Its purity, however, translates to a slightly lower strength, with higher purities exhibiting slightly weaker properties.

We offer comprehensive technical support and services for Aluminium Tube usage, encompassing technical guidance, production assistance, and beyond. Our skilled technicians are equipped to assist you in addressing any challenges or concerns that may arise during the use of your products.

Technical Parameters:

| Main Size) | State | Outside Diameter /mm | Wall Thickness /mm | Length /m | Tensile Strength /MPa | Non-proportional Elongation Strength /MPa | Elongation After Break A50/mm | ||

| Model Number | |||||||||

| Main Size | |||||||||

| Series 1 | 1050 1060 1070 1050A | O | 20-32 | 0.8-2.0 | 5-15 | ≤20.00 | 60~95 | ≥70 | ≥25.00 |

| H14 | ≤10.00 | 100~135 | ≥70 | ≥5.00 | |||||

| Series 3 | 3003 3103 3A21 | O | ≤20.00 | 95~130 | ≥35 | ≥25.00 | |||

| H12 | ≤15.00 | 115~150 | ≥75 | ≥12.00 | |||||

| H14,H24 | ≤10.00 | 135~165 | ≥110 | ≥6.00 | |||||

| H28 | ≤3.00 | ≥180 | ≥145 | ≥3.00 | |||||

1050

| Model Name | Model Number | Outside Diameter /mm | Wall Thickness/mm | Maximum Length/m | Length/mm | Tensile Strength /MPa | Non-proportional Elongation Strength /MPa | Elongation After Break A50/mm |

| Main Size | Series 1 | 20-32 | 0.8-2.0 | 5000-15000 | ||||

| Series 3 | ||||||||

| Example | 1050 | 35 | 1.8 | 18 | 9000 | 100~135 | ≥80 | ≥5.00 |

| 21 | 1.0 | 7000 | ||||||

| 31 | 1.5 | 6000 | ||||||

| 32 | 1.9 | 8000 |

You can then find a form at this link to download and fill out the basic information.

Send it to the specified e-mail address and our engineers will quote you according to the technical parameters.

http://mao.ecer.com/test/al-tubes.com/cases/how-to-order-15643.html

How to order:

You can then download a form from this website and fill it out with basic details.

Send it to the provided e-mail address, and our engineers will price you based on the technical specifications.

http://mao.ecer.com/test/al-tubes.com/cases/how-to-order-15643.html

Alternatively, you can download the Technical Data Requirements Sheet directly.

Yuneng Product Requirements Table.docx

FAQ:

http://mao.ecer.com/test/al-tubes.com/cases/faq-15908.html