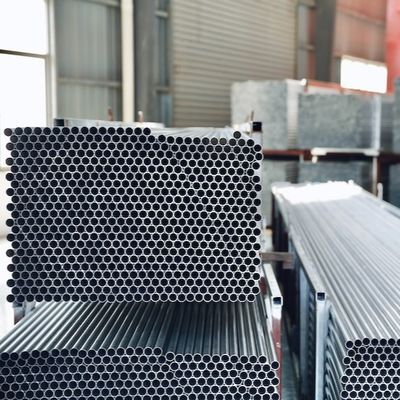

3003 H14 Aluminum Alloy Tube With External Diameter Of 18.5mm Silver Color Radiator Aluminum Tube

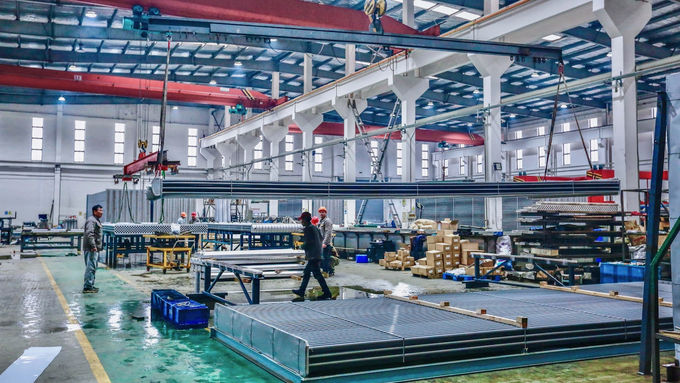

| Place of Origin | Changzhou, Jiangsu Province, China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3003 | State | H14 |

| Shape | Round | Outside Diameter/mm | 18.5 |

| Thickness/mm | 1.1 | ||

| High Light | External Diameter Aluminum Alloy Tube,Silver Color Aluminum Alloy Tube,18.5mm Aluminum Alloy Tube |

||

3003 H14 Aluminum Alloy Tube With External Diameter Of 18.5mm Silver Color Radiator Aluminum Tube

Here we shed light on key distinctions between cold drawn and hot extruded aluminum tubes.

1. When creating cold drawn aluminum pipes, our skilled craftspeople gradually thin down, then stretch out each metal bar until attaining the ideal dimension. Hot extruded tubes are shaped via heating metal bars and forcing them through an extruder.

2. Cold drawn pipes boast a sleek finish, eliminating the need for additional surface treatments. Conversely, hot extruded tubes bear clear extrusion marks, requiring specific procedures for defect removal.

3. Differentiation In Brief:

(1) Strength: Cold drawn aluminum pipes possess superior strength with fewer degrees of flexibility compared to hot extruded ones, offering significant toughness and flex.

(2) Durability: Machining cold drawn tubes is straightforward, allowing deep drawing and pressing. Hot extruded tubes' versatility is more confined, suited primarily for simpler processes such as cutting and drilling.

(3) Corrosion Resistance: Cold drawn pipes offer an elegant, burr-free surface due to superior grain size, providing excellent corrosion resistance. However, hot extruded surface markings can worsen with potential burring and corrosive damage.

4. Applications: Our meticulously designed cold drawn aluminum tubes serve versatile purposes in instrument precision fabrication, car components, electronic goods, among others. Hot extruded tubes specialize in complex part creation, cold-working components, and energy-efficient door/window systems. These production techniques, surface quality, performance characteristics, and other features establish unique differences between cold drawn and hot extruded aluminum tubes. For best results, select the tube type according to your precise requirements.

Compared to standard aluminum alloy pipes, our cold drawn aluminum alloy square pipes offer these benefits:

Exceptional strength. Our cold drawn aluminum alloy square tubes showcase superior yield and tensile strengths, high hardness, capable of enduring substantial pressure and tension.

Extraordinary corrosion resistance. Their uniformly smooth surfaces provide excellent protection against rust and corrosion.

Superior manufacturing standards. Our cold drawn aluminum alloy square tubes, artfully crafted via cold Drawing technique, exhibit a sleek, flawless finish, exceptional precision, and remarkable tolerance against deformation.

In conclusion, these cold-drawn alloys are elite, lightweight, high-strength materials, perfectly suited for challenging settings such as aerospace, automotive manufacturing, or construction engineering.

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Applications:

While extruded aluminum is extremely common in a wide range of applications, it is not suitable for everything. Any requirement for elevated properties may turn toward cold finished product as raw material. Aerospace and defense products requiring high strength often specify cold finished bar, as well as a host of automotive applications.