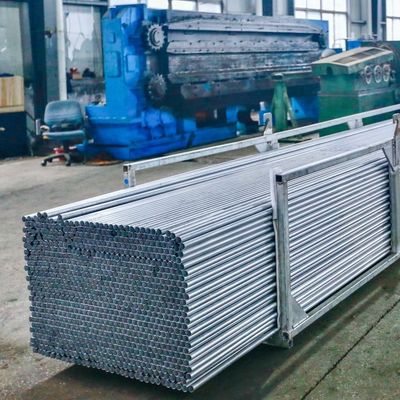

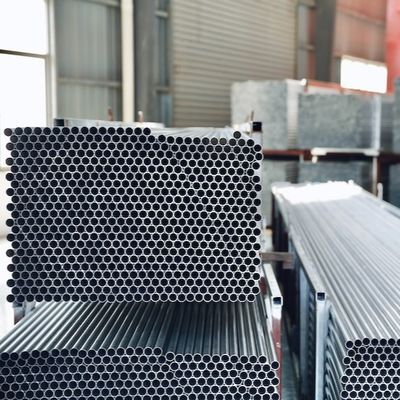

Grade 3003 H28 Aluminum Alloy Tube Corrosion Resistance External Diameter 8.5mm

| Place of Origin | Changzhou, China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Number | 3003 | Material | Aluminum Or Aluminum Alloy |

|---|---|---|---|

| State | H28 | Application | Heat Exchange Equipment,Air-conditioner, Refrigerator |

| Tensile Strength | ≥180Mpa | Non-proportional Elongation Strength MPa | ≥145 |

| Elongation After Break A50mm | ≥3.00 | Outside Diameter/mm | 8.5 |

| Wall Thickness/mm | 0.25 | Length | Customized |

| Shape | Coil | Specification | Refer To National Stamdars Or Customer Requirements |

| High Light | H28 Aluminum Alloy Tube,Corrosion Resistance Aluminum Alloy Tube,8.5mm Aluminum Alloy Tube |

||

Grade 3003 H28 Aluminum Alloy Tube Corrosion Resistance External Diameter 8.5mm

Our advanced aluminum wire, with an optimal external diameter of 8mm and a polished inner thickness of 0.24mm, upgrades product excellence remarkably. Its precision enables it to accommodate a range of complex applications. Constantly impressing, our 3003H28 aluminum wire shines brightly in diverse environments like advanced machinery and streamlined automated production lines.

By harnessing aluminum pipe processing methods, the durability and malleability of 3003H28 aluminum wire is significantly boosted, boosting its practicality even more. Stretching, bending, stamping - all operations maintain its remarkable flexibility, enhancing the quality and output of circular pipes.

3003 H28 aluminum wire, produced by us, boasts noted plasticity, corrosion resistance, and welding capability. Through post-hardening, it exhibits exceptional strength and steadfastness, backed by accurate size control and exceptional quality assurance. This bar is celebrated as a frontrunner for refined processing and high-performance needs, earning widespread applause. As an industry maverick, we stand tall.

Features:

Our 3003H28 aluminum wire, meticulously designed by us, has proven robust in diverse industry sectors due to its high functionality. The exceptional blend of its chemical and physical attributes makes it applicable across many areas. Often employed in making containers, heat exchangers, and chemical treatment gear, its exceptional welding capabilities suit various welding components perfectly.

Choosing our 3003H28 aluminum wire promises several perks. First off, we value quality, employing state-of-the-art methods and stringent quality controls to meet highest standards. Secondly, it's highly resilient. The 3003H28 alloy from where our wire originates exhibits outstanding corrosion and wear resistance, ensuring constant functionality even under intense conditions for extended durations. With precise sizing, courtesy of our precision machinery and deliberate size testing protocols, each wire offers millimeter accuracy that suits your requirements precisely.

Lastly, our 3003H28 aluminum wire's adaptability is extraordinary. Its superior physical, chemical, and welding characteristics allow it to cater to an extensive array of industries' diverse needs. Regardless of what field you're in, our 3003H28 aluminum wire stands out as an essential tool because it is indeed an all-rounder.

Production Process:

Coil pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-heat treatment-flaw detection -forming-inspection-finished product packaging

Stright pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-straightening-flaw detection-fine cutting-cleaning-heat treatment-inspection-finished product packaging

Techical Parameters:

Heat Exchanger Aluminum Tube

The main production specifications are listed as follows:

| Model Number | State | Wall Thickness mm | Tensile Strength MPa | Non-proportional Elongation Strength MPa | Elongation After Break A50mm |

| 1050 1060 1070 1050A | O | ≤20.00 | 60~95 | ≥70 | ≥25.00 |

| H14 | ≤10.00 | 100~135 | ≥70 | ≥5.00 | |

| 3003 3103 3A21 | O | ≤20.00 | 95~130 | ≥35 | ≥25.00 |

| H12 | ≤15.00 | 115~150 | ≥75 | ≥12.00 | |

| H14,H24 | ≤10.00 | 135~165 | ≥110 | ≥6.00 | |

| H28 | ≤3.00 | ≥180 | ≥145 | ≥3.00 |

Specifications can be customized according to customer requirements.

Applications:

Condensator

Evaporimeter

Air-conditioning

Icebox

Home freezer

Industrial freezer

Cold storage with cold exhaust pipe

Small warm wind

Lipstick shell

Eyebrow pen shell

Air conditioning connection pipe

Car water tank connecting pipe

Car air-conditioning connection pipe

Microchannel heat exchanger connecting tube

etc.

HOW TO ORDER

Firstly,here is a more detailed product description about Aluminum Alloy Tubes of Heat Exchanger.

You can then download a form from this website and fill it out with basic details.

Send it to the provided e-mail address, and our engineers will price you based on the technical specifications.

http://mao.ecer.com/test/al-tubes.com/cases/how-to-order-15643.html

Alternatively, you can download the Technical Data Requirements Sheet directly.

Yuneng Product Requirements Table.docx