3003 Aluminum Tube Optimal Performance for Refrigeration and Air Conditioning Systems

| Place of Origin | Changzhou, China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 tons |

| Price | negotiation |

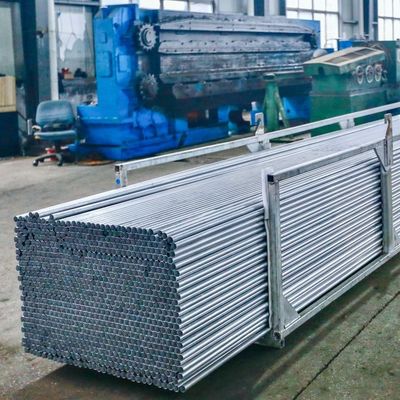

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Number | 3003 | Material | Aluminum Or Aluminum Alloy |

|---|---|---|---|

| State | H28 | Application | Heat Exchange Equipment,Air-conditioner, Refrigerator |

| Tensile Strength | ≥180Mpa | Non-proportional Elongation Strength MPa | ≥145 |

| Elongation After Break A50mm | ≥3.00 | Outside Diameter/mm | 9.8 |

| Wall Thickness/mm | 0.6 | Length | Customized |

| Shape | Coil | Specification | Refer To National Stamdars Or Customer Requirements |

| High Light | Air Conditioning Systems Aluminum Tube,3003 Aluminum Tube,Refrigeration Aluminum Tube |

||

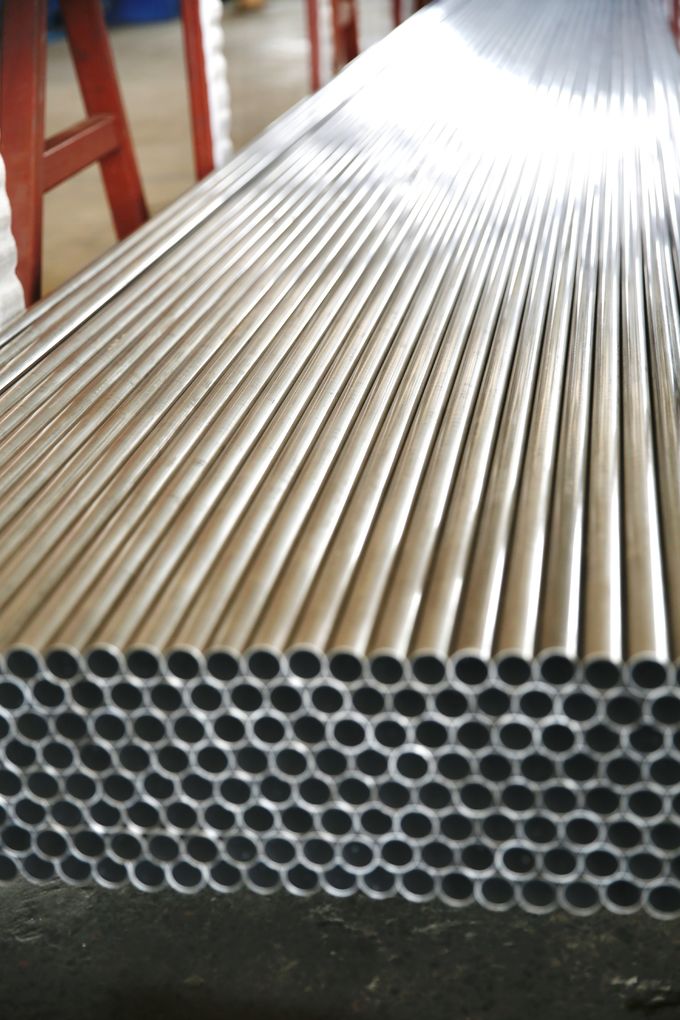

3003 Aluminum Tube Optimal Performance for Refrigeration and Air Conditioning Systems

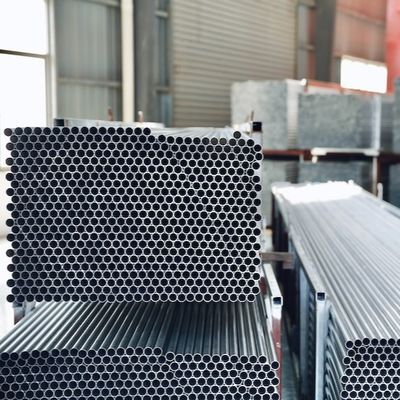

Crafted from 3003H28 aluminum tube pancake coils, our product is a testament to engineering excellence. It boasts a robust rust-resistant alloy composition, with a carefully calibrated 1.0%-1.5% manganese content, ensuring top-tier performance across a range of applications. Its versatile design facilitates seamless integration into diverse industrial settings, making it a perfect fit for multiple scenarios.

With its unparalleled resistance to corrosion, this aluminum tube is ideally suited for heat exchangers, playing a crucial role in enhancing the efficiency of refrigeration and air conditioning systems. Furthermore, its superior welding characteristics simplify component connections, thereby bolstering overall stability and reliability.

Measuring a precise diameter of 9.8 mm and a thickness of 0.6 mm, this tube is a powerhouse in diverse industries, including air conditioners, refrigerators, and automotive air conditioning units. It efficiently meets the varying demands of various applications, demonstrating its adaptability and versatility.

In conclusion, the 3003H28 aluminum tube pancake coil holds a prestigious position as an essential metal in refrigeration and air conditioning. It offers an unparalleled, durable, and cost-effective solution for modern refrigeration equipment, ensuring long-term performance and value.

Features:

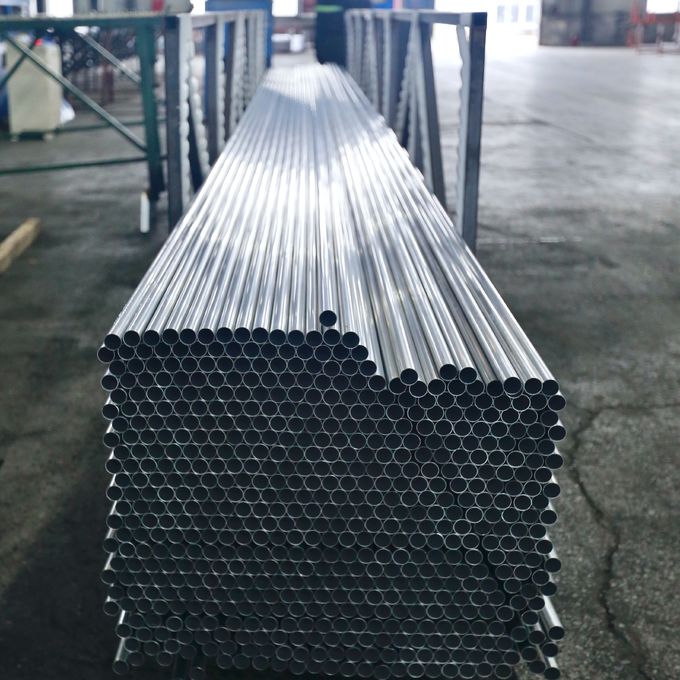

We are proud of our exceptional machinery, which produces aluminum round tubes with impeccable precision. Our unique 3003 tube boasts remarkable corrosion resistance, flexibility, and robustness. This harmonious blend of industrial precision and annealing results in exceptional mechanical properties following cold working.

What's more, the sleek reflective finish of our aluminum tubing guards against corrosive effects in harsh chemical environments, ensuring stable performance. Its reliable sealing feature arises from an evenly distributed aluminum foil core that effectively blocks moisture and odors. This makes it an ideal choice for high-pressure applications, providing rock-solid pipeline security.

Additionally, our 3003 cylinder tube demonstrates exceptional heat resistance, ensuring durability even under elevated temperatures. Cold-worked enhancements maintain consistent performance, seamlessly adapting to diverse high-temperature scenarios.

Moreover, the easy assembly of our tubes offers added convenience. Their lightweight and flexible design facilitate effortless bending and connection. Ultimately, their outstanding stability ensures safety while enhancing overall efficiency.

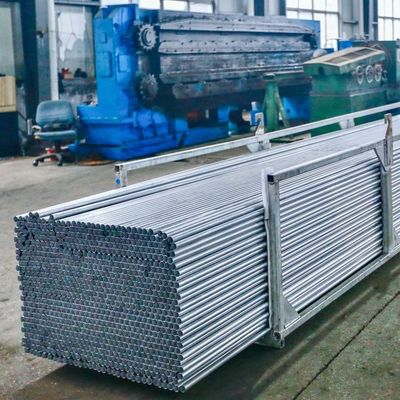

Production Process:

Coil pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-heat treatment-flaw detection -forming-inspection-finished product packaging

Stright pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-straightening-flaw detection-fine cutting-cleaning-heat treatment-inspection-finished product packaging

echical Parameters:

Heat Exchanger Aluminum Tube

The main production specifications are listed as follows:

| Model Number | State | Wall Thickness mm | Tensile Strength MPa | Non-proportional Elongation Strength MPa | Elongation After Break A50mm |

| 1050 1060 1070 1050A | O | ≤20.00 | 60~95 | ≥70 | ≥25.00 |

| H14 | ≤10.00 | 100~135 | ≥70 | ≥5.00 | |

| 3003 3103 3A21 | O | ≤20.00 | 95~130 | ≥35 | ≥25.00 |

| H12 | ≤15.00 | 115~150 | ≥75 | ≥12.00 | |

| H14,H24 | ≤10.00 | 135~165 | ≥110 | ≥6.00 | |

| H28 | ≤3.00 | ≥180 | ≥145 | ≥3.00 |

Specifications can be customized according to customer requirements.

Applications:

Condensator

Evaporimeter

Air-conditioning

Icebox

Home freezer

Industrial freezer

Cold storage with cold exhaust pipe

Small warm wind

Lipstick shell

Eyebrow pen shell

Air conditioning connection pipe

Car water tank connecting pipe

Car air-conditioning connection pipe

Microchannel heat exchanger connecting tube

etc.