Exceptional Induction Density Aluminum Coil Tubing for Cooling and Heat Exchange

| Place of Origin | Changzhou, China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 1050 |

| Minimum Order Quantity | 3 tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Number | 1050 | Material | Aluminum Or Aluminum Alloy |

|---|---|---|---|

| State | H14 | Application | Heat Exchange Equipment,Air-conditioner, Refrigerator |

| Tensile Strength | 100Mpa-135Mpa | Non-proportional Elongation Strength MPa | ≥80 |

| Elongation After Break A50mm | ≥5 | Outside Diameter/mm | 28mm |

| Wall Thickness | 1.5mm | Length | Customized |

| Shape | Coil | Specification | Reference To National Standards Or Customized According To Customer Requirements |

| High Light | Cooling Aluminum Coil Tubing,Exceptional Induction Density Aluminum Coil Tubing,Heat Exchange Aluminum Coil Tubing |

||

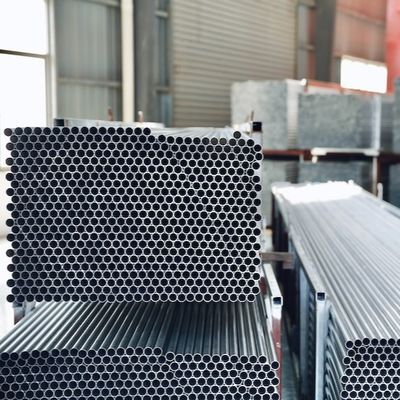

Exceptional Induction Density Aluminum Coil Tubing for Cooling and Heat Exchange

Our offering primarily encompasses 1 series, 3 series, 6 series, and our proprietary, specially formulated anti-corrosion aluminum alloy. We meticulously select only the finest, brand-name high-quality remelting rods for all our raw materials, ensuring impeccable quality from the outset.

Our products find their primary application in diverse cooling heat exchange tubes, particularly in air conditioning units, refrigerators, and heating/ventilation systems. We offer a comprehensive range of ruler and coil tubes to cater to different application scenarios. Boasting excellent quality, our heat exchanger tubes feature high-quality remelted aluminum rods, stringent quality control measures, and are produced using state-of-the-art large-tonnage extruders.

Employing a hot extrusion cold drawing process, our tubes exhibit high product density, remarkable heat transfer performance, and superior corrosion resistance, among other benefits. Furthermore, our commitment to precision and attention to detail ensures tight tolerances and consistent quality throughout.

Our advanced production processes, including specialized heat treatment techniques, guarantee precise dimensions, low leakage rates, and exceptional induction density. Our products are tailored to meet the unique needs of each customer, with specifications and performance characteristics that can be customized to suit individual requirements. Remarkably, we can produce tubes with lengths reaching up to 18 meters.

In summary, our offering not only meets but exceeds the standards set by the industry, fulfilling the demands of even the most discerning users. Our products are the epitome of reliability, performance, and adaptability, ensuring satisfaction in every application.

Features:

Equipped with a comprehensive array of aluminum tube production equipment and rigorous testing procedures, our company ensures impeccable product quality and mechanical performance. With strict control over the production process, we achieve remarkable precision, maintaining a tolerance range as narrow as ±0.02 mm.

Specializing in the manufacture of diverse specifications of aluminum coil and straight tube, our offerings are tailored to meet the demands of refrigeration and heat exchange equipment across industries. Leveraging cutting-edge production techniques and specialized heat treatment processes, we consistently uphold stringent quality standards to deliver the most dependable products to our valued customers.

Techical Parameters:

Heat Exchanger Aluminum Tube

The main production specifications are listed as follows:

| Model Number | State | Wall Thickness mm | Tensile Strength MPa | Non-proportional Elongation Strength MPa | Elongation After Break A50mm |

| 1050 1060 1070 1050A | O | ≤20.00 | 60~95 | ≥70 | ≥25.00 |

| H14 | ≤10.00 | 100~135 | ≥70 | ≥5.00 | |

| 3003 3103 3A21 | O | ≤20.00 | 95~130 | ≥35 | ≥25.00 |

| H12 | ≤15.00 | 115~150 | ≥75 | ≥12.00 | |

| H14,H24 | ≤10.00 | 135~165 | ≥110 | ≥6.00 | |

| H28 | ≤3.00 | ≥180 | ≥145 | ≥3.00 |

The specifications in the form can be customized according to customer's requirements.

Applications:

Condensator

Evaporimeter

Air-conditioning

Icebox

Home freezer

Industrial freezer

Cold storage with cold exhaust pipe

Small warm wind

Lipstick shell

Eyebrow pen shell

Air conditioning connection pipe

Car water tank connecting pipe

Car air-conditioning connection pipe

Microchannel heat exchanger connecting tube

etc.

Production Process:

Coil pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-heat treatment-flaw detection -forming-inspection-finished product packaging

Stright pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-straightening-flaw detection-fine cutting-cleaning-heat treatment-inspection-finished product packaging

Support and Services:

We support and provide technical services for the use of aluminum pipes and assist customers to solve the production problems arising during the actual use process. Including the performance detection of aluminum pipe, technical analysis, the use of the back channel, aluminum pipe welding, aluminum pipe pipe, aluminum pipe bending, finished product leakage detection, etc., at the same time in the use of related problems, we will also assist customers to solve problems in the first time. And make corresponding adjustments according to the actual situation.

FAQ.:

Q1: What kind of material alloy is the product?

A1: Currently, there are 1 series, 3 series aluminum alloy.

Q2: What state and performance of the aluminum pipe can be produced?

A2: can produce from hard state to soft state and interval performance products

Q3: Can I customize the product specifications and requirements?

A3: Different specifications and states can be customized according to the requirements, such as fixed ruler straight pipe and coil pipe

Q 4: What is the minimum starting order volume?

A 4: The minimum order volume is 3 tons.