3103 H12 Outside Diameter 6.8 Mm Corrosion Resistant Aluminum Alloy Heat Pipe Silver

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3103 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

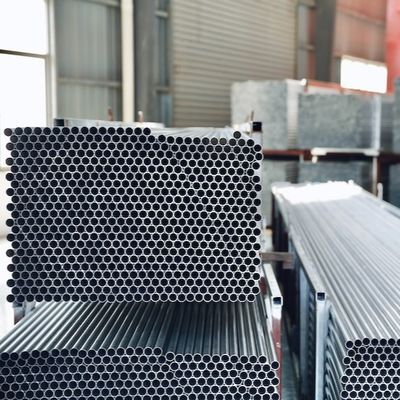

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3103 | State | H12 |

| Shape | Round | Outside Diameter/mm | 6.8 |

| Thickness/mm | 0.4 | ||

| High Light | 3103 Alloy Heat Pipe,H12 Alloy Heat Pipe,Corrosion-resistant Alloy Heat Pipe |

||

3103 H12 Outside Diameter 6.8 mm Corrosion-resistant Aluminum Alloy Heat Pipe Silver

Introduction

The aluminum tube cold drawing method is beautifully designed to craft aluminum rods precisely, fulfilling unique requirements. Each draw subtly alters the rod's cross-section, enhancing both surface finish and accuracy. This impressive technique is perfect for production of high-grade aluminum alloy pipes, proving useful in diverse applications such as aviation, automotive, rail transit, and electronics.

Procedure

This meticulous process includes vital steps such as selecting suitable bars, prep work, first draw, air drying, second draw, heat therapy, third draw, straightening, pickling, and chilly treatment. Primary stages comprise stretching the rod initially on machinery followed by optimizing pipe sizes through subsequent draws. The final draw not only smoothes off any burrs but also enhances the accuracy of the tubular surface quality.

Traits

This procedure presents these distinct qualities:

1. Exceptional Accuracy: Cold drawing produces flat alloy tubing with flatness under 0.02mm and dimensional precision of up to 0.05mm;

2. Adaptability: Manipulating tube characteristics like irregularities or thinning walls is achieved effortlessly through this technique;

3. Minimal Surface Roughening: This approach effectively controls tube surfaces, offering a superior finish.

Utilization

Cold drawing on aluminum tubes is a preferred technique to produce top-tier alloy pipes. It finds use in various sectors like aviation, transport, and electronics.

【 Conclusion 】

The art of cold drawingaluminium tube creates top-tier precision tubes, featuring superb surface smoothness, precise sizes, and scarce burr creation. This process shines in industries such as aviation, automobiles, rail transit, and electronics, embodying considerable market potential.

Committed to innovation in the global cooling, heating, and renewable sectors, our firm offers intelligent, corrosion resistant aluminum materials and parts. We persistently refine and develop industry forefront technology to offer the best benefits for our customers and partners, promoting mutual cooperation.

http://mao.ecer.com/test/al-tubes.com/cases/power-plant-air-cooling-tube-product-pamphlet-15462.html

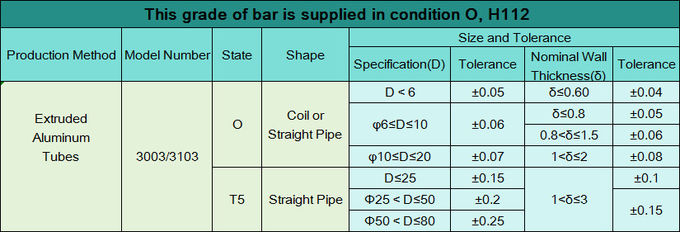

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

We provide 1 series of pure aluminum and 3 series of corrosion-resistant aluminum tube, can also be customized according to customer needs of non-standard specifications of the heat exchange equipment aluminum tube. Welcome to consult.

Applications:

Though extruded aluminum is ubiquitous across various fields, it's not suitable for all projects. For increased qualities, cold-rolled product could be considered. The aerospace and defense sectors often opt for this, in addition to several automotive applications.