Corrosion Resistant Class 3003 Aluminum Alloy Tubes With External D10 Mm For Automotive Radiator

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Radiator Aluminum Alloy Tubing |

|---|---|---|---|

| Model Number | 3003 | State | O |

| Shape | Round | Outside Diameter/mm | 10 |

| Thickness/mm | 1.65 | ||

| High Light | D10 Aluminum Alloy Tubes,Corrosion-resistant Aluminum Alloy Tubes,Automotive Radiator Aluminum Alloy Tubes |

||

Corrosion-resistant Class 3003 Aluminum Alloy Tubes With An External D10 mm For Automotive Radiator

About aluminum alloy material

3003 - known for its impressive corrosion resistance, is an appreciated AL-Mn alloy. Its strength falls behind industrial pure aluminum's capacity but heat treatment isn't viable to strengthen it further. Hence, we employ cold working techniques to improve its performance.

Mechanical properties

Tensile strength: σb (MPa) 142-178

Conditional yield strength: σ0.2 (MPa) ≥ 115

Specimen size: all wall thickness

Note: room temperature longitudinal mechanical properties of pipe

Why Aluminum Tube Selected Over Copper Tube in Automobile Radiator Systems?

The Use of Aluminum in Automobile Radiators

Lighter hybrid and electric vehicles would benefit from reduced fuel consumption and longer battery life. Weight optimization in the car's structure appears promising, while streamlined cooling systems could magnify the gains even further.

Trends in Car Radiator Component Composition

The exceptional thermal and electrical conductivity of aluminum, together with its impressive three times denser than copper status, suggest a compelling rationale to swap it for copper in an auto radiator. It may lead to a remarkable decrease in system weight, potentially up to a considerable 50%!

Heightened Copper Prices Could Offer Increased Savings on Aluminum Tubes

Copper, essential for promoting decarbonization and renewable energy adoption, is predicted to get increasingly scarce soon. This likely means that there might not be enough copper supply in the near future, possibly causing its price to surge by more than 60%.

In comparison, aluminum stands out as a budget-friendly choice due to its stability in pricing (low volatility). While current technology allows it conduct electricity at merely two-thirds the speed of copper, research hopes that modifying its metal composition could enhance its future commercial viability.

These are the areas where aluminum fits in:

* Car radiators

* Busbars

* Battery cables

* Backbone technology

* Module connections in electric vehicles

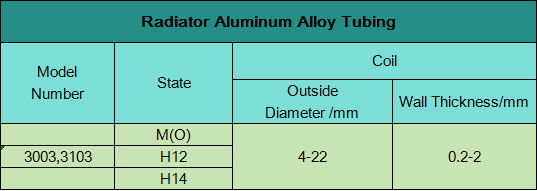

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

HOW TO ORDER

Firstly,here is a more detailed product description about Aluminum Tubes for Car Radiaror(Automotive Water Tanks).

You can then find a form at this link to download and fill out the basic information.

Send it to the specified e-mail address and our engineers will quote you according to the technical parameters.

http://mao.ecer.com/test/al-tubes.com/cases/how-to-order-15643.html