Aluminium 3103 H12 Extruded Aluminium Tube For External Diameter 16.8mm Radiator

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3103 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

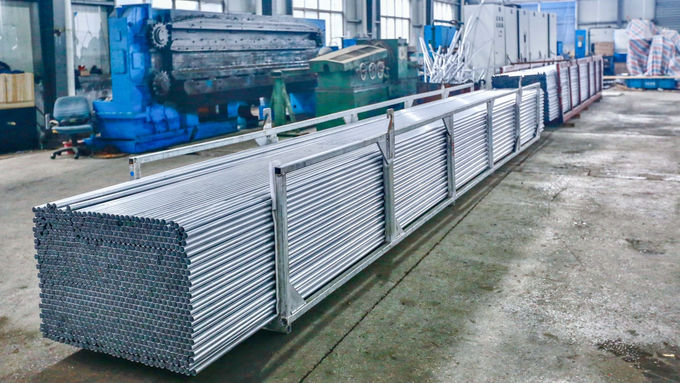

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3103 | State | H12 |

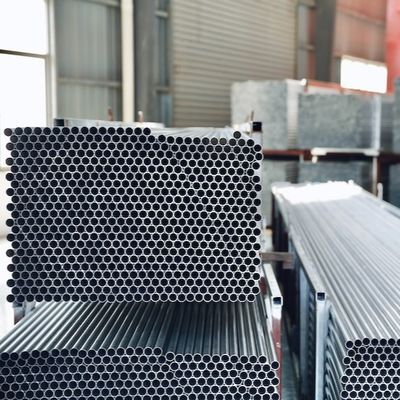

| Shape | Round | Outside Diameter/mm | 16.8 |

| Thickness/mm | 1.85 |

Aluminium 3103 H12 Extruded Aluminium Tube For External Diameter 16.8mm Radiator

Delve into our custom aluminium alloy cold-drawn tube's fabrications

Derived from superior strength and lightweight material - chilled drawn aluminum alloy square tubes present outstanding durability and resistance against rust. Thanks to their cold drawing precision, they possess an even surface and a high resistance to deformations. These qualities, make them ideal supplies for crafting structures, aerospace components, car components, etc.

Popularity lies with aluminum alloy square tubes like Series 1000 (pure aluminum), 2000 (copper blend), 3000 (manganese), 5000 (magnesium), 6000 (low magnesium/silicon) and 7000 (zinc addition). They each hold unique chemical and physical features.

Chemical Makeup of Chilled Dished Aluminum Alloy Square Tubes:

Our assortment of chilled drawn aluminum alloy square tubes mainly consist of aluminum, copper, manganese, magnesium, silicon, zinc, iron, titanium, and more. Predominantly, aluminum forms up to a standard of 90% or higher. The composition varies in grade and use.

Mechanical Properties of Chilled Dished Aluminum Alloy Square Tubes:

When it comes to mechanical performance of these tubes, crucial factors come into play such as yield strength, tensile strength, elongation, and hardness. This can be influenced by changes in the tubing's composition and specifications. Generally speaking, alloy pipes offer better performance than regular ones.

Discovering Differences between Cold-drawn Aluminium Alloy Square Tube and Regular Aluminium Alloys Tube.

Compared with ordinary aluminum alloy pipes, cold drawn aluminum alloy square pipes have the following advantages:

Superb strength. Our cold drawn aluminum alloy square tubes exhibit beefed-up yield and tensile strengths, high hardness, capable of enduring more pressure and tension.

Exceptional durability. Their smooth, flat surface grants outstanding corrosion resistance, reducing vulnerability to rusting or erosion.

Sophisticated manufacturing method. The cold drawing process renders a flat, precise surface resistant to warping or distortion.

In essence, these cold drawn aluminum alloy square tubes are indisputably an efficient structural material, delivering exceptional strength, natural resistance to corrosion, and user-friendliness - perfect for industries like aerospace, automobile, and construction.

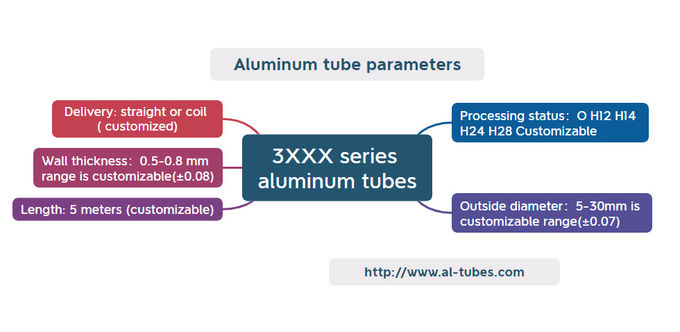

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Applications:

While extruded aluminum is extremely common in a wide range of applications, it is not suitable for everything. Any requirement for elevated properties may turn toward cold finished product as raw material. Aerospace and defense products requiring high strength often specify cold finished bar, as well as a host of automotive applications.