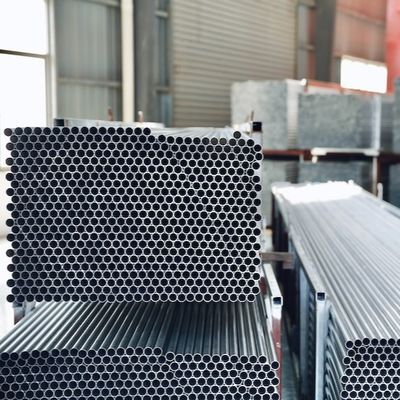

3103 Standard Aluminum Tube H14 Outside Diameter 12.8mm Wall Thickness 0.38mm Heat Exchanger

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3103 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3103 | State | H14 |

| Shape | Round | Outside Diameter/mm | 12.8 |

| Thickness/mm | 0.38 | ||

| High Light | Heat Exchanger 3103 Standard Aluminum Tube,H14 3103 Standard Aluminum Tube,0.38mm 3103 Standard Aluminum Tube |

||

3103 Standard Aluminum Tube H14 Outside Diameter 12.8mm Wall Thickness 0.38mm Heat Exchanger

The Exquisite Artistry of Aluminium Tube Cold Drawing: Enhancing Tube Excellence and Dimensional Precision

The aluminium tube cold drawing procedure meticulously manufactures aluminium rods according to exact requirements. Every cold drawing phase shrinks the rod's cross section, guaranteeing an impeccable surface finish and dimensionally precise results. Esteemed for its proficiency in crafting premium quality aluminium alloy tubes, esteemed for its application across a multitude of sectors including aviation, automotive, rail transit, electronics and beyond.

Our exquisite 3003H14 aluminum wire deserves your attention. This remarkable product is well designed and manufactured by our esteemed company and has made significant contributions in numerous industrial sectors.

Its powerful chemical and physical properties enable it to stand out in different fields. We often use this product to make a variety of containers, heat exchangers and chemical processing equipment. In addition, its superior welding performance often leads us to use it in manufacturing a variety of welding parts. By choosing our 3003H14 aluminum wire, you will experience several benefits. First of all, excellent quality-we use the most advanced production technology and strict quality assurance measures to ensure that every product adhere to the highest standards. Second, durability-the unique properties of our 3003H14 aluminum alloy provide superior corrosion resistance and abrasion resistance, enabling them to maintain consistent performance in a variety of harsh conditions.

In addition, accurate sizing-we utilize precise mechanical and meticulous sizing methods to ensure that each aluminum wire is accurate to the nearest millimeter to meet your specific requirements. Finally, versatility-the widely used 3003H14 aluminum wire, with its special physical, chemical and welding properties, spans all industries. No matter what your area of work is, you may encounter 3003H14 aluminum wires. This is an all-encompassing aluminum wire that can meet a variety of needs.

In our aluminum pipe production, cold extrusion technology has a number of significant advantages: first, high accuracy: through the precision cold-drawn process of manufacturing aluminum pipe, the surface smoothness can be less than 0.02 mm, dimensional accuracy is limited to about 0.05 mm; second, the construction of complex surfaces: this cold drawing process gives the aluminum tube a stronger plastic deformation ability, so that it can easily shape a variety of complex shapes, including irregular and thin-walled tube types; finally, excellent aesthetic quality: after cold-drawn aluminum tube, the surface burrs significantly reduced, thus improving the overall appearance of the degree of beauty.

It is worth mentioning that the cold-drawn aluminum tube processing can also produce high-quality caliber, widely used in various high-end aluminum alloy pipe in many fields, for example:

1. Aerospace industry: Used in the manufacture of aircraft, rockets and high-speed vehicles;

2. Transportation Field: in the automobile, train, subway and other industries have been widely used;

3. Electronic Science and technology field: mainly used for packaging electronic products as well as the manual production of conductive tubes and other aspects.

【 Conclusion 】

Examining the Merits and Business Potential of the Aluminum Tube Cold Drawing Procedure: The cold drawing methodology applied to aluminum tubes serves as a pivotal strategy for crafting high-accuracy cylindrical products from this metal. This technique exhibits a myriad of exceptional features, including unparalleled surface refinement, exacting dimensional accuracy, and negligible machine tool chatter, consequently gaining significant traction across various sectors like aerospace, automobile, rail transportation, electronic devices, etc.

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Applications:

While extruded aluminum remains an incredibly popular choice across various applications, its suitability isn't universal. In instances demanding superior physical attributes, manufacturers might opt to use cold finished product as their primary raw material. Cold finished bar is frequently preferred for aerospace and defense sectors that require substantial strength, alongside an array of automotive solutions.

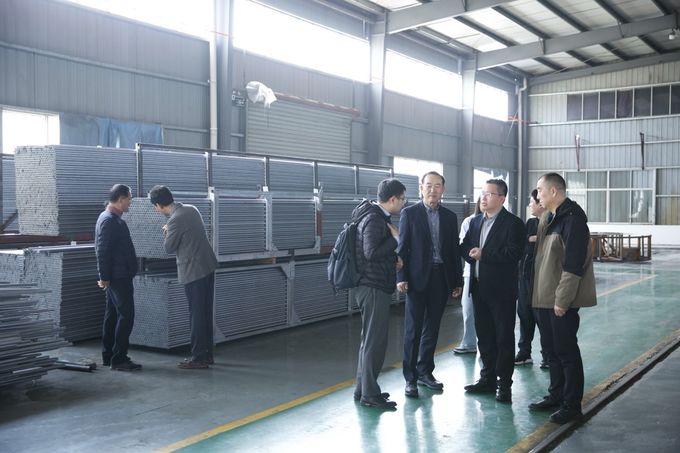

Our robust organization boasts of a superb technical collective. Comprising substantial industrialisation expertise, this esteemed team collaborates closely with several eminent universities and research establishments including Xi'an Jiaotong University, Nankai University, and Changzhou University, aiming to establish an avant-garde Innovation R & D Laboratory together.

You can then download a form from this website and fill it out with basic details.

Send it to the provided e-mail address, and our engineers will price you based on the technical specifications.

http://mao.ecer.com/test/al-tubes.com/cases/how-to-order-15643.html

We can provide technical support and services for the use of Aluminium Tube, including technical guidance, production assistance and so on. Our experienced technicians can help you solve any problems you may encounter with your products.