3103 H12 Round Aluminum Extruded Tube With 16.9mm Outer Diameter For Silver Color Radiator

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3103 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Anti-corrosion | Product Name | Cold Drawn Aluminium Tube |

|---|---|---|---|

| Model Number | 3103 | State | H12 |

| Shape | Round | Outside Diameter/mm | 16.9 |

| Thickness/mm | 1.9 |

3103 H12 Round Aluminum Extruded Tube With 16.9mm Outer Diameter For Silver Color Radiator

Welcome to explore our meticulously crafted, customised aluminium alloy cold-drawn tubes.

Crafted from robust yet light-weight materials - our chilled drawn aluminum alloy square tubes are renowned for their exceptional durability and rust-resistance. The cold drawing process guarantees a smooth, flat surface and high resistance to deformation. These attributes make them excellent materials for diverse applications such as structure building, aerospace parts, car components, etc.

Our range boasts popular grades like Series 1000 (pure aluminum), 2000 (copper blend), 3000 (manganese), 5000 (magnesium), 6000 (low magnesium/silicon) and 7000 (zinc addition). Each possesses distinct chemical and physical properties.

Chemical Composition of Chilled Dished Aluminum Alloy Square Tubes:

Our chilled drawn aluminum alloy square tubes primarily comprise aluminum, copper, manganese, magnesium, silicon, zinc, iron, titanium, among others. Typically, aluminum constitutes over 90%. The composition may vary depending on the grade and application.

Mechanical Properties of Chilled Dished Aluminum Alloy Square Tubes:

The mechanical performance of these tubes is determined by key factors including yield strength, tensile strength, elongation, and hardness. These can be affected by variations in the tube's composition and specifications. Generally, alloy pipes outperform regular ones.

Exploring the Difference between Cold-drawn Aluminium Alloy Square Tube and Regular Aluminium Alloys Tube.

Compared with ordinary aluminum alloy pipes, cold drawn aluminum alloy square pipes have the following advantages:

Impressive strength. Our cold drawn aluminum alloy square tubes boast enhanced yield and tensile strengths, excellent hardness, able to withstand significant pressure and tension.

Outstanding durability. With their smooth flat surface, they offer superior corrosion resistance, minimizing risk of rusting or erosion.

Sophisticated production. Our cold drawing technique ensures a flat, accurate surface that resists warping or distortion.

In summary, our cold drawn aluminum alloy square tubes are undoubtedly a superb structural material, offering remarkable strength, natural anti-corrosion properties, and ease of use - making them ideal for sectors such as aviation, automotive, and construction.

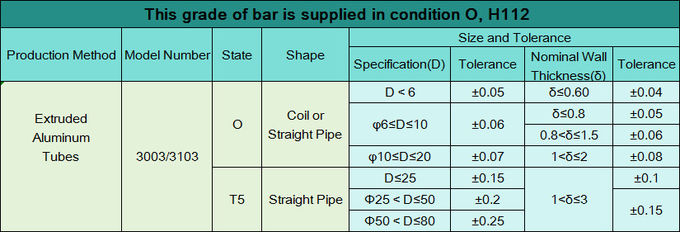

Techical Parameters:

Radiator Aluminum Alloy Tubing

|

Model Number |

State | Coil | |

|

Outside Diameter /mm |

Wall Thickness/mm | ||

| 3003,3103 | M(O) | 4-22 | 0.2-2 |

| H12 | |||

| H14 | |||

(Technical requirements refer to national standards or customer technical quality requirements for production)

Applications:

Aluminum extrusion is common across many sectors, but it's not perfect for every situation. For specific needs demanding enhanced attributes, cold finished item might be the answer. High-strength necessities in aerospace and defense industries frequently call for cold finished bars along with various automotive applications.