Heat Exchanger 3003 H14 Aluminum Tube H18 Aluminum Alloy Round Tubes

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO14001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Number | 3003 | Material | Aluminum Or Aluminum Alloy |

|---|---|---|---|

| State | H14 H18 | Application | Heat Exchange Equipment,Air-conditioner, Refrigerator |

| Tensile Strength | 115Mpa-150Mpa | Non-proportional Elongation Strength MPa | ≥75 |

| Elongation After Break A50mm | ≥12.00 | Outside Diameter/mm | Customized |

| Wall Thickness/mm | ≤15.00 | Length | Customized |

| Shape | Coil | Specification | Refer To National Stamdars Or Customer Requirements |

| High Light | heat exchanger 3003 H14 Aluminum Tube,3003 H14 Aluminum Tube 150Mpa,H18 aluminum alloy round tube |

||

The heat exchanger uses 3003 H14 H18 aluminum alloy round tubes

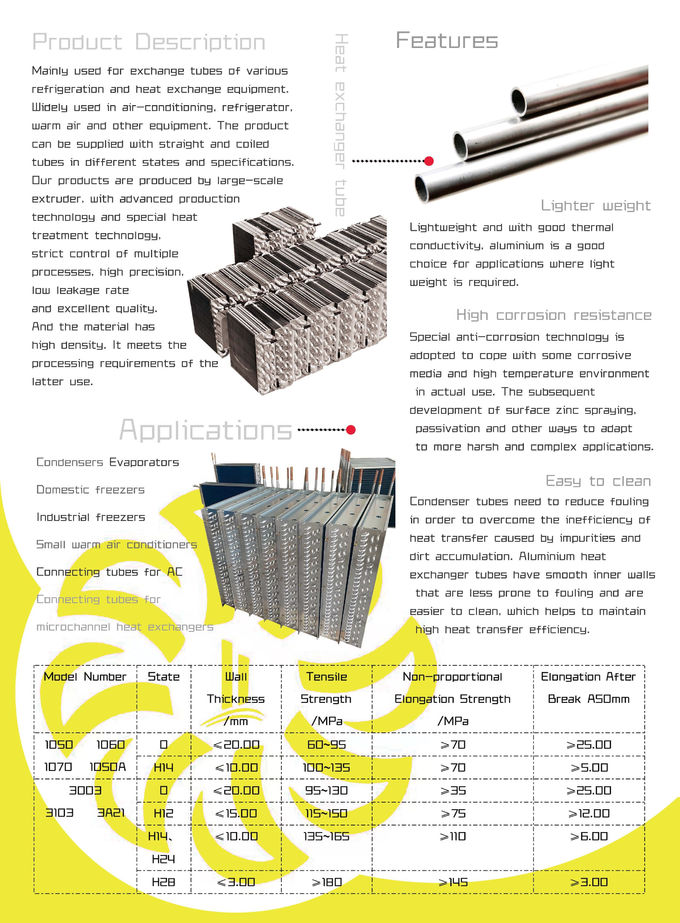

Product Description:

Aluminum tubes for heat exchangers should mainly be made of a series of different series of aluminum alloys used in different environments, including 3 series, 1 series, 6 series, 5 series, etc. These aluminum alloys are widely used in the manufacture of heat exchange tubes for refrigeration equipment due to their excellent properties. These heat exchangers can be used in various refrigeration equipment, such as air conditioners, refrigerators, and heating systems. In order to meet the needs of different equipment, we provide products in two different states: straight pipe and coiled pipe, which can meet the needs of different equipment manufacturers and users.

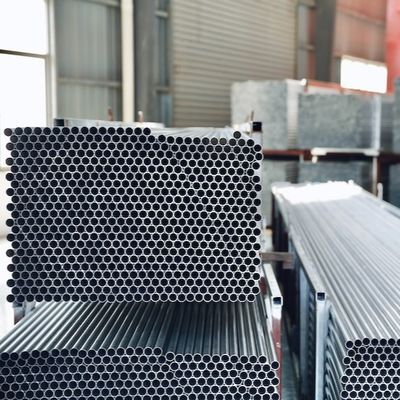

Our company's aluminum tube products for heat exchangers adopt internationally advanced large-scale extruder production technology, cutting-edge production technology and professional heat treatment technology. We strictly control various process parameters to ensure stable and reliable product quality. Through the application of these processes and technologies, we create products with high precision, low leakage rate, and excellent quality, allowing users to obtain more efficient and longer-life refrigeration equipment.

The aluminum alloy material used in the aluminum tubes for heat exchangers has a higher density, making the product quality more reliable. At the same time, we strictly abide by the processing specifications for back road use to ensure the processing accuracy and service life of the product. During the production process, we also focus on environmental protection and sustainable development, using environmentally friendly materials and production processes to ensure the greenness of our products.

Features:

The company has a complete set of advanced equipment for producing aluminum tubes, as well as a complete set of equipment for testing aluminum tubes. During the production process, the company adopts strict quality control measures to ensure that the quality and mechanical properties of each aluminum tube are optimized with higher precision and smaller tolerance ranges. This high-precision control can be achieved within a range of 0.02mm, which fully reflects the company's pursuit of excellence in aluminum tube production.

1. Good chemical corrosion resistance: The inner wall of the aluminum tube is as smooth as a mirror. This structure makes the aluminum tube have good corrosion resistance. Even when exposed to corrosive substances, it can effectively resist chemical erosion and ensure long-term use of the pipeline.

2. Good sealing: The middle layer of the aluminum pipe is aluminum foil with uniform thickness. This structure can effectively prevent the penetration of oxygen, water vapor and odor, ensuring the air tightness of the pipe. Even under high pressure, aluminum pipes can maintain good sealing performance, ensuring the safety and stability of the pipeline.

3. Good high temperature resistance: Aluminum tubes have good high temperature resistance and can be durable in high temperature environments. Even if used for a long time at high temperatures, the performance of the aluminum tube will not decrease significantly, fully meeting various usage scenarios that require high temperature environments.

4. Convenient construction: Aluminum pipes are light in weight, flexible and easy to construct, and can meet the needs of bending and connection.

Techical Parameters:

Heat Exchanger Aluminum U Tube

The main production specifications are listed as follows:

| Model Number | State | Wall Thickness mm | Tensile Strength MPa | Non-proportional Elongation Strength MPa | Elongation After Break A50mm |

| 1050 1060 1070 1050A | O | ≤20.00 | 60~95 | ≥70 | ≥25.00 |

| H14 | ≤10.00 | 100~135 | ≥70 | ≥5.00 | |

| 3003 3103 3A21 | O | ≤20.00 | 95~130 | ≥35 | ≥25.00 |

| H12 | ≤15.00 | 115~150 | ≥75 | ≥12.00 | |

| H14,H24 | ≤10.00 | 135~165 | ≥110 | ≥6.00 | |

| H28 | ≤3.00 | ≥180 | ≥145 | ≥3.00 |

Specifications can be customized according to customer requirements.

Applications:

Condensator

Evaporimeter

Air-conditioning

Icebox

Home freezer

Industrial freezer

Cold storage with cold exhaust pipe

Small warm wind

Lipstick shell

Eyebrow pen shell

Air conditioning connection pipe

Car water tank connecting pipe

Car air-conditioning connection pipe

Microchannel heat exchanger connecting tube

etc.

Production Process:

Coil pipe

Raw material procurement-

inspection-cleaning-extrusion-coiling-heat treatment-flaw detection -forming-inspection-finished product packaging

Stright pipe

Raw material procurement-inspection-cleaning-extrusion-coiling-straightening-flaw detection-fine cutting-cleaning-heat treatment-inspection-finished product packaging

HOW TO ORDER

Firstly,here is a more detailed product description about Aluminum Alloy Tubes of Heat Exchanger.

You can then download a form from this website and fill it out with basic details.

Send it to the provided e-mail address, and our engineers will price you based on the technical specifications.

http://mao.ecer.com/test/al-tubes.com/cases/how-to-order-15643.html

Alternatively, you can download the Technical Data Requirements Sheet directly.

Yuneng Product Requirements Table.docx