Parallel Flow Micro Channel Condenser Heat Exchanger AC Aluminum Fins Fin Width 23.5mm

| Place of Origin | Jiangsu China |

|---|---|

| Brand Name | YUN NENG |

| Certification | SO9001 ISO14001 ISO45001 |

| Model Number | 6815 |

| Minimum Order Quantity | negotiation |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 6,000w per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

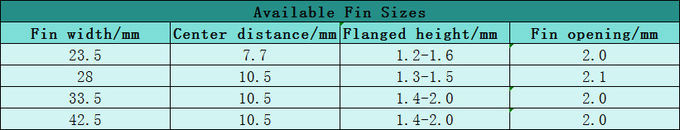

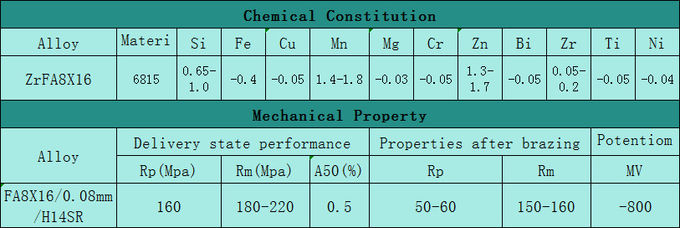

x| Alloy | FA8X16/0.08mm/H14SR | Material | 6815 |

|---|---|---|---|

| Fin Width/mm | 23.5 | Center Distance/mm | 7.7 |

| Flanged Height/mm | 1.2-1.6 | Fin Opening/mm | 2.0 |

| High Light | 23.5mm Micro Channel Condenser,Micro Channel Condenser 23.5mm,Parallel Flow aluminum fins |

||

Parallel Flow Heat Exchanger Micro Channel Condenser AC Aluminum Fins Fin Width 23.5mm

Product Description:

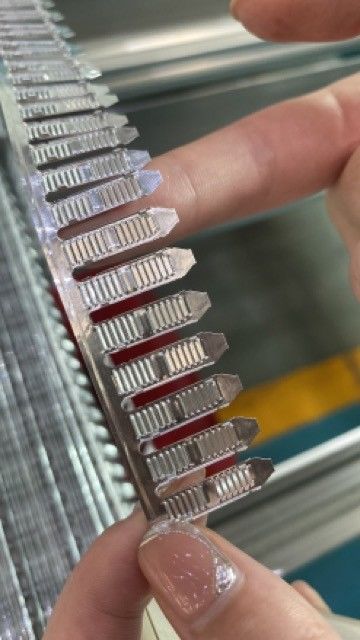

The design of Insert fin

Heat fin at least single extension and wrapped in flat tube, air conditioning greenhouse condition or defrosting, condensate / frost water condensation on the fin, into the lower drainage tank, along the drain to extend direction, through the delay in the vertical part of the flat tube, quickly flow to the bottom of the heat exchanger, solved the parallel flow heat exchanger because of flat tube, wing water drainage problems, make the product under the condition of air conditioning greenhouse does not produce water plugging, eliminate the wind resistance caused by water blocking and heat bridge between fins. The heat transfer performance of the heat exchanger is stable, and the thermal curve of the unit is stable. The single side of the fin is open, forming is difficult, after many tests, the mold is used to solve the problem, and the wing shutter, corrugated plate, double shutter, flat plate and other places to strengthen the wind side heat transfer, to meet the needs of different working conditions.

Production Process:

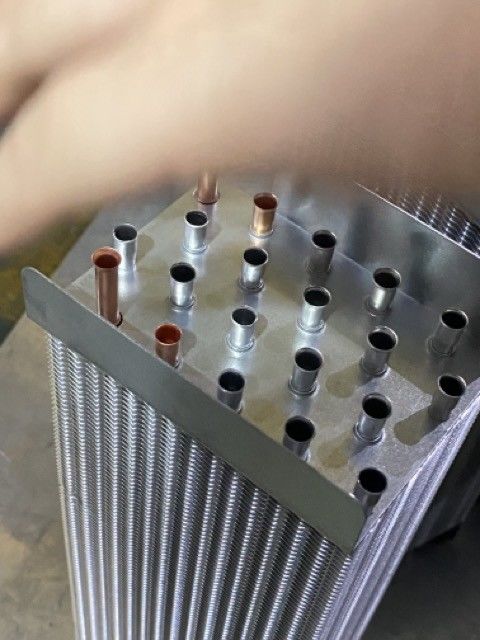

Fin stamping →aggregate→header assembly→press forming→degrease spray (FLUX) drying,

Preheating→(NB) →brazing→ forced air cooling →plastic connection pipe welding →helium leak detection→ultrasonic cleaning→coating→ drying →sheet metal assembly →final inspection→packaging

Features:

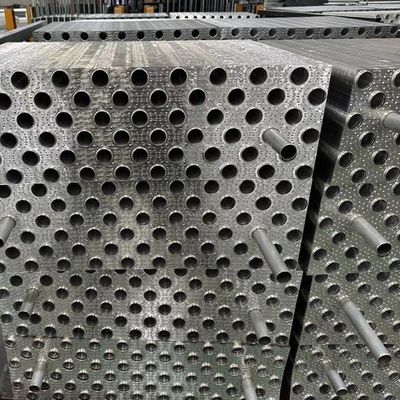

YUNNENG designs and manufactures high-performance microchannel condenser insert fins displaying a number of advantages over traditional condenser fin designs, the key of those are:

Conformity and reliability

Fings are very easy to break and deform after stamping and forming, and the automatic assembly machine(Manufacturing Equipment-Filling and molding machine) is used to avoid wing deformation and inconsistent wing spacing.

Frost work condition

With better frosting performance, 30% better than the traditional microchannel performance.

Passivation + hydrophilic coating

Techical Parameters:

Household heat pump and air-conditioning condenser;

Applications:

Commercial multi-line evaporator, condenser;

Commercial heat pump system (module machine) evaporator;

Bus and car air-conditioning evaporator, condenser;

Commercial air-conditioning duct machine evaporator;

Electric locomotive, rv, truck, engineering vehicle condensers, evaporator;

New energy vehicle air conditioning condenser, evaporator...

Etc.