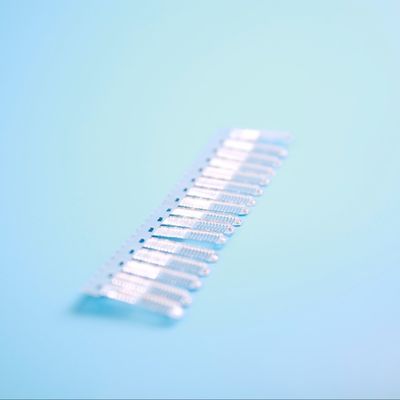

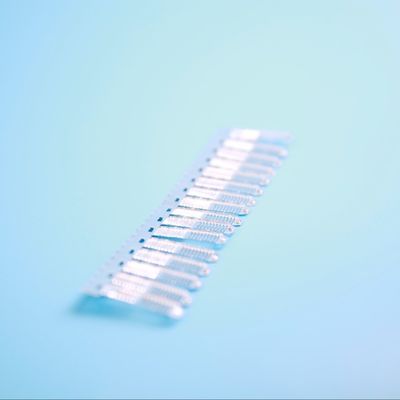

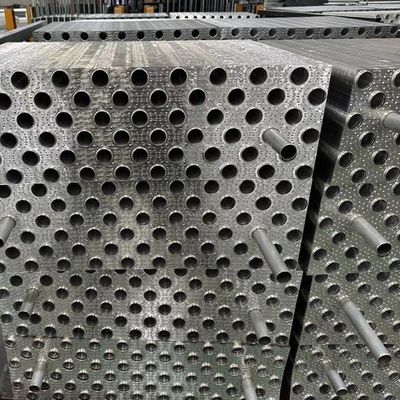

Microchannel Condenser Insert Fins For AC Fin Width 28mm Micro Condenser Coil

| Place of Origin | Jiangsu China |

|---|---|

| Brand Name | YUN NENG |

| Certification | SO9001 ISO14001 ISO45001 |

| Model Number | 6815 |

| Minimum Order Quantity | negotiation |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 6,000w per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Alloy | FA8X16/0.08mm/H14SR | Material | 6815 |

|---|---|---|---|

| Fin Width/mm | 28 | Center Distance/mm | 10.5 |

| Flanged Height/mm | 1.3 | Fin Opening/mm | 2.0 |

| High Light | 28mm microchannel condenser,FA8X16 aluminum microchannel condenser,1.3mm Micro Condenser Coil tube |

||

Microchannel Condenser Insert Fins For AC Fin Width28mm Micro Condenser Coil

Product Description:

What is a microchannel condenser?

Microchannel condensers are designed to act as condensing coils in a wide range of air conditioning, cooling and refrigeration applications and equipment. The condensers are designed for use with a wide range of refrigerants. These include HFC and HFO based gases and derivative mixtures, natural refrigerants and blends.

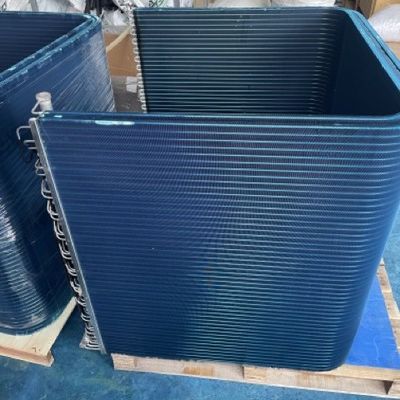

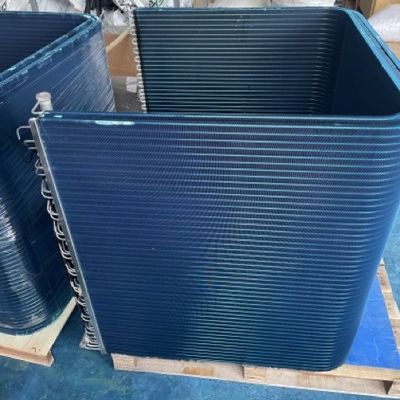

The design includes inlet and outlet headers with flat multi-port microchannel tubes and fins. The headers are brazed in a controlled atmosphere furnace.

Production Process:

Fin stamping →aggregate→header assembly→press forming→degrease spray (FLUX) drying,

Preheating→(NB) →brazing→ forced air cooling →plastic connection pipe welding →helium leak detection→ultrasonic cleaning→coating→ drying →sheet metal assembly →final inspection→packaging

Features:

YUNNENG designs and manufactures high performance microchannel condenser fins that have a number of advantages over traditional condenser fin designs, the most important of which are:

Conformity and Reliability

The fins are very easily broken and deformed after stamping and moulding, and the automatic assembly machine (Manufacturing Equipment-Filling and Moulding Machine) is used to avoid fin deformation and inconsistent fin spacing.

Frost working condition

With better freezing performance, 30% better than the traditional microchannel performance.

Passivation + Hydrophilic Coating

Techical Parameters:

| Chemical Constitution | ||||||||||||

| Alloy | Material | Si | Fe | Cu | Mn | Mg | Cr | Zn | Bi | Zr | Ti | Ni |

| ZrFA8X16 | 6815 | 0.65-1.0 | -0.4 | -0.05 | 1.4-1.8 | -0.03 | -0.05 | 1.3-1.7 | -0.05 | 0.05-0.2 | -0.05 | -0.04 |

| Mechanical Property | ||||||||||||

| Alloy | Delivery state performance | Properties after brazing | Potentiometric | |||||||||

| Rp(Mpa) | Rm(Mpa) | A50(%) | Rp | Rm | MV | |||||||

| FA8X16/0.08mm/H14SR | 160 | 180-220 | 0.5 | 50-60 | 150-160 | -800 | ||||||

| Available Fin Sizes | |||

| Fin width/mm | Center distance/mm | Flanged height/mm | Fin opening/mm |

| 23.5 | 7.7 | 1.2-1.6 | 2.0 |

| 28 | 10.5 | 1.3-1.5 | 2.1 |

| 33.5 | 10.5 | 1.4-2.0 | 2.0 |

| 42.5 | 10.5 | 1.4-2.0 | 2.0 |

Applications:

Household heat pump and air-conditioning condenser;

Commercial multi-line evaporator, condenser;

Commercial heat pump system (module machine) evaporator;

Bus and car air-conditioning evaporator, condenser;

Commercial air-conditioning duct machine evaporator;

Electric locomotive, rv, truck, engineering vehicle condensers, evaporator;

New energy vehicle air conditioning condenser, evaporator...

Etc.

Support and Services:

The fin, micro-channel cooling tube and collecting tube can be customized according to customer's requirements, product width up to 1500mm, length direction can be any size.