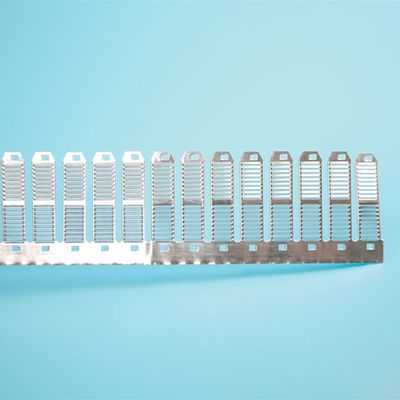

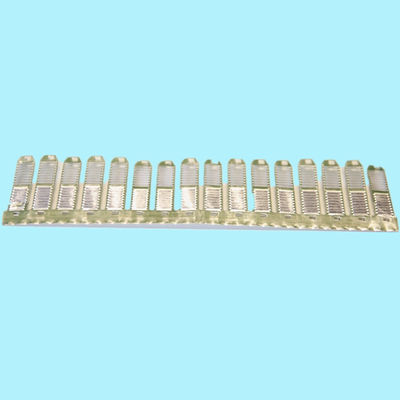

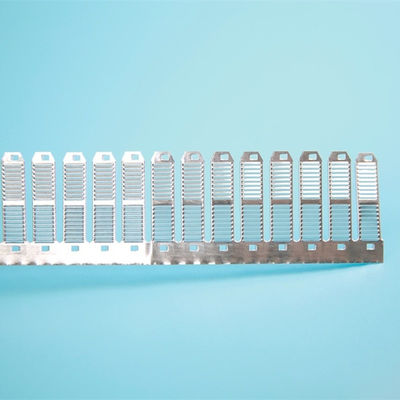

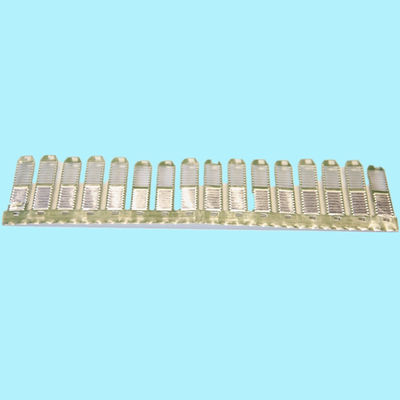

Aluminum Micro Channel Condenser Corrosion-Resistant Fin Material 6815 Fin Width 29mm

| Place of Origin | Jiangsu China |

|---|---|

| Brand Name | YUN NENG |

| Certification | SO9001 ISO14001 ISO45001 |

| Model Number | 6815 |

| Minimum Order Quantity | negotiation |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 6,000w per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

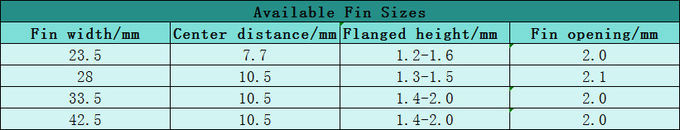

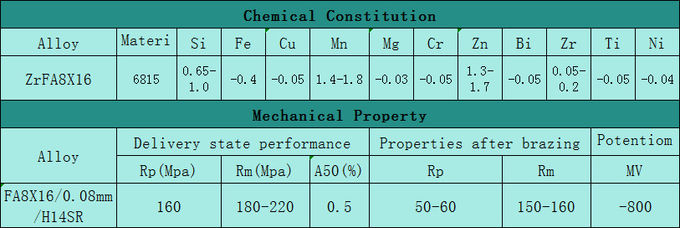

x| Alloy | FA8X16/0.08mm/H14SR | Material | 6815 |

|---|---|---|---|

| Fin Width/mm | 29 | Center Distance/mm | 8.8 |

| Flanged Height/mm | 1.2-1.8 | Fin Opening/m | 2.0 |

| High Light | 8.8mm Micro Channel Condenser,160mpa Micro Channel Condenser,ac aluminium condenser 29mm |

||

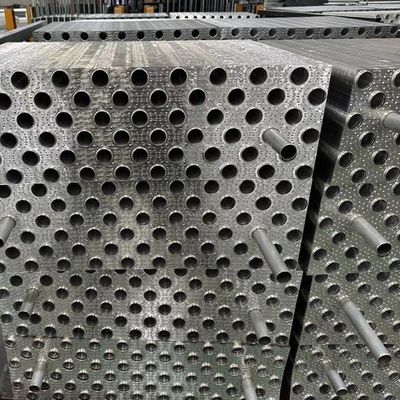

Aluminum corrosion-resistant fin material 6815 fin width for micro-channel condenser 29mm

Product Description:

The aluminum plate fin heat exchanger consists of aluminum plates and aluminum fins. It has the following characteristics:

1. Lightweight. The density of aluminum alloy is relatively small, and the processed plates and fins are very light, resulting in a lighter weight for the entire heat exchanger.

2. Beautiful appearance. The surface of the aluminum plate fin heat exchanger adopts spraying or oxidation treatment, which is durable and has a beautiful appearance, and can meet different needs.

3. High heat dissipation efficiency. The heat dissipation efficiency of aluminum plate fin heat exchangers is very high because the thermal conductivity of aluminum alloy is good, and the shape and spacing of fins are precisely calculated, which can increase the heat exchange area and increase the heat exchange effect.

4. Low resistance. The aluminum plate fin heat exchanger has spacious flow channel spacing, low flow resistance, and free flow of fluid, reducing power consumption.

5. Good corrosion resistance. Aluminum alloy has good oxidation resistance and can resist the corrosion of various chemicals on the heat exchanger, with a long service life.

Production Process:

Fin stamping →aggregate→header assembly→press forming→degrease spray (FLUX) drying,

Preheating→(NB) →brazing→ forced air cooling →plastic connection pipe welding →helium leak detection→ultrasonic cleaning→coating→ drying →sheet metal assembly →final inspection→packaging

Features:

The aluminum finned tube has an appropriate increase in the overall heat transfer coefficient, and its heat transfer effect is also relatively good. The main reason is that its surface is free of any burrs and wrinkles, and the overall appearance is very bright and beautiful.

Therefore, its strength will be higher and there will be no adverse phenomena such as scaling and dust formation. Aluminum alloy radiators are basically made of aluminum tubes, so their thermal resistance is small and they have high heat transfer performance. Moreover, their anti-corrosion function is also very powerful. The most important thing is that they have relatively small activity losses, and even when processed under long-term uneven cold and hot conditions, their appearance does not show deformation.

Techical Parameters:

Household heat pump and air-conditioning condenser;

Applications:

Commercial multi-line evaporator, condenser;

Commercial heat pump system (module machine) evaporator;

Bus and car air-conditioning evaporator, condenser;

Commercial air-conditioning duct machine evaporator;

Electric locomotive, rv, truck, engineering vehicle condensers, evaporator;

New energy vehicle air conditioning condenser, evaporator...

Etc.