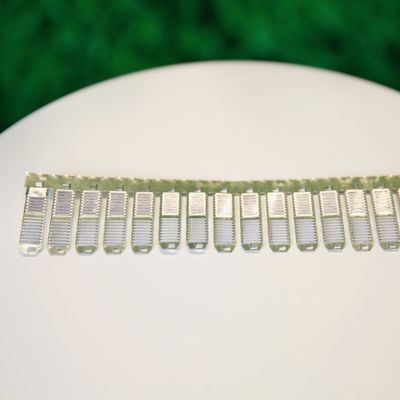

33.5 mm Microchannel Condenser Fin High-efficiency Heat Transfer Aluminum Alloy Tube

| Place of Origin | Jiangsu China |

|---|---|

| Brand Name | Yun Neng |

| Certification | SO9001 ISO14001 ISO45001 |

| Model Number | 6815 |

| Minimum Order Quantity | negotiation |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 6,000w per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Alloy | FA8X16/0.08mm/H14SR | Material | 6815 |

|---|---|---|---|

| Fin Width/mm | 33.5 | Center Distance/mm | 10.5 |

| Flanged Height/mm | 1.4 | Fin Opening/mm | 2.0 |

| High Light | 33.5 mm microchannel condenser,microchannel condenser Heat Transfer tube,33.5mm aluminum cooling fins |

||

33.5 mm Micro-channel Condenser Fin High-efficiency Heat Transfer Aluminum Alloy Tube

Product Description:

What exactly is a microchannel condenser?

Microchannel heat exchanger was first used in electronic field, which solved the large-scale“Thermal barrier” problem in integrated circuit. Compared with conventional heat exchangers, microchannel heat exchangers have higher heat transfer efficiency, higher heat response rate and better controllability, lower noise and stable operation, better pressure bearing capacity, better corrosion resistance, lower cost and lower material consumption under the same heat exchange requirements.

Microchannel condensers are designed to be used as condensing coils in a variety of air conditioning, cooling and refrigeration applications and equipment. This condenser is specially designed for various refrigerants.

Production Process:

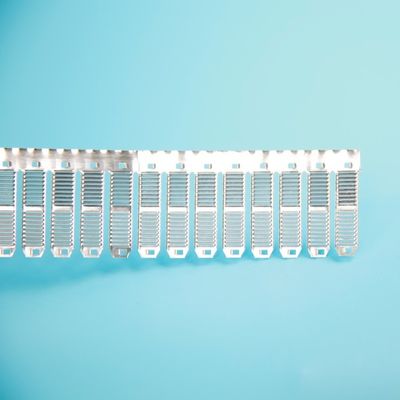

Fin stamping →aggregate→header assembly→press forming→degrease spray (FLUX) drying,

Preheating→(NB) →brazing→ forced air cooling →plastic connection pipe welding →helium leak detection→ultrasonic cleaning→coating→ drying →sheet metal assembly →final inspection→packaging

Features:

Yun Neng Group company

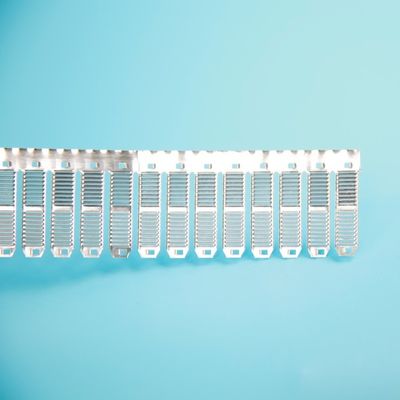

The design and manufacture of high performance micro-channel condenser fins have many advantages compared with the traditional design of condenser fins.

One of the most important is: consistency and reliability fins after stamping is easy to break and deformation, and the use of automatic assembly machine (manufacturing equipment-filling molding machine) to avoid fin deformation and fin spacing inconsistent.

The freezing condition has better freezing performance, which is 30% higher than the traditional microchannel. Passivation + hydrophilic coating.

The frosting condition has better frosting performance, which is 30% better than the traditional microchannel.

Techical Parameters:

| Chemical Constitution | ||||||||||||

| Alloy | Material | Si | Fe | Cu | Mn | Mg | Cr | Zn | Bi | Zr | Ti | Ni |

| ZrFA8X16 | 6815 | 0.65-1.0 | -0.4 | -0.05 | 1.4-1.8 | -0.03 | -0.05 | 1.3-1.7 | -0.05 | 0.05-0.2 | -0.05 | -0.04 |

| Mechanical Property | ||||||||||||

| Alloy | Delivery state performance | Properties after brazing | Potentiometric | |||||||||

| Rp(Mpa) | Rm(Mpa) | A50(%) | Rp | Rm | MV | |||||||

| FA8X16/0.08mm/H14SR | 160 | 180-220 | 0.5 | 50-60 | 150-160 | -800 | ||||||

| Available Fin Sizes | |||

| Fin width/mm | Center distance/mm | Flanged height/mm | Fin opening/mm |

| 23.5 | 7.7 | 1.2-1.6 | 2.0 |

| 28 | 10.5 | 1.3-1.5 | 2.1 |

| 33.5 | 10.5 | 1.4-2.0 | 2.0 |

| 42.5 | 10.5 | 1.4-2.0 | 2.0 |

Applications:

Household heat pump and air-conditioning condenser;

Commercial multi-line evaporator, condenser;

Commercial heat pump system (module machine) evaporator;

Bus and car air-conditioning evaporator, condenser;

Commercial air-conditioning duct machine evaporator;

Electric locomotive, rv, truck, engineering vehicle condensers, evaporator;

New energy vehicle air conditioning condenser, evaporator...

Etc.

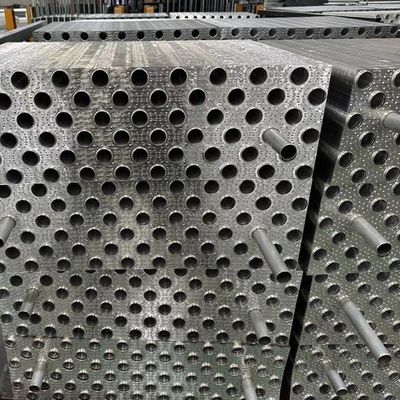

Support and Services:

The fin, micro-channel cooling tube and collecting tube can be customized according to customer's requirements, product width up to 1500mm, length direction can be any size.