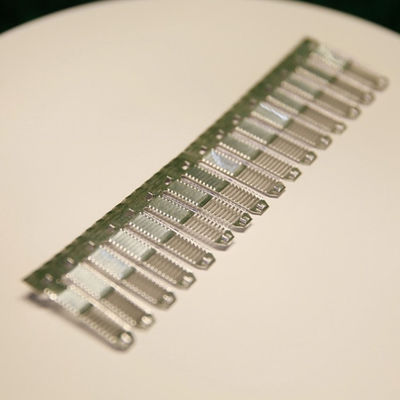

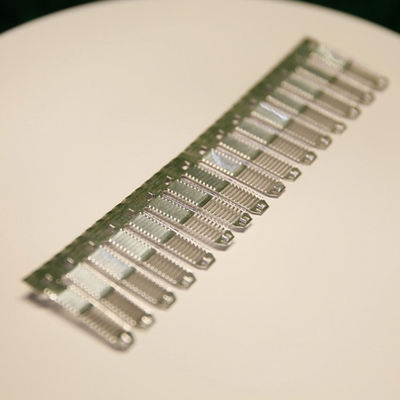

29.5mm Aluminum Corrosion-Resistant Fin Material 6815 Fin Width For Microchannel Condenser

| Place of Origin | Changzhou Jiangsu China |

|---|---|

| Brand Name | YUN NENG |

| Certification | SO9001 ISO14001 ISO45001 |

| Model Number | 6815 |

| Minimum Order Quantity | negotiation |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 6,000w per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Alloy | FA8X16/0.08mm/H14SR | Material | 6815 |

|---|---|---|---|

| Fin Width/mm | 29.5 | Center Distance/mm | 10.5 |

| Flanged Height/mm | 1.2-1.6 | Fin Opening/mm | 2.0 |

| High Light | 29.5mm microchannel condenser,microchannel condenser ISO14001,aluminum radiator fins 29.5mm |

||

29.5 mm Aluminum corrosion-resistant fin material 6815 fin width for micro-channel condenser

Product Description:

1, What is a microchannel condenser

A microchannel condenser is a heat exchanger in a refrigeration system, characterized by the use of microchannels made of metal plates to achieve fluid flow and heat transfer. Microchannel condensers are widely used in fields such as household air conditioners, automotive air conditioners, and commercial refrigerators due to their high efficiency, portability, small footprint, and low cost.

2, The refrigeration system principle of microchannel condenser

The refrigeration system of a microchannel condenser consists of four main parts: a compressor, a condenser, an expansion valve, and an evaporator. During the refrigeration process, when the refrigerant comes out of the compressor, it enters the microchannel condenser first. In the condenser, the refrigerant releases heat due to contact with ambient air and becomes liquid, which is then converted into a low-pressure liquid refrigerant through an expansion valve and enters the evaporator. In the evaporator, the refrigerant will absorb heat from the air and evaporate into a gaseous state. After the refrigerant enters the compressor again, the cycle is restarted.

Features:

Unlike capillary refrigeration systems, microchannel condensers do not require capillaries to control the flow of refrigerant. In a capillary refrigeration system, due to the damping effect of the capillary, the refrigerant can only flow slowly within the capillary, controlling the flow rate and pressure of the refrigerant. Due to the small flow resistance of the liquid refrigerant in the microchannel of the microchannel condenser, the liquid refrigerant can freely flow in the microchannel, thereby achieving control of refrigerant flow and pressure.

The refrigeration system of microchannel condensers does not require capillaries to control the flow of refrigerant, as the liquid refrigerant flow resistance in the microchannels of microchannel condensers is relatively small. Microchannel condensers have the advantages of high efficiency, portability, small footprint, and low cost, and are widely used in fields such as household air conditioners, automotive air conditioners, and commercial refrigerators.

Techical Parameters:

| Chemical Constitution | ||||||||||||

| Alloy | Material | Si | Fe | Cu | Mn | Mg | Cr | Zn | Bi | Zr | Ti | Ni |

| ZrFA8X16 | 6815 | 0.65-1.0 | -0.4 | -0.05 | 1.4-1.8 | -0.03 | -0.05 | 1.3-1.7 | -0.05 | 0.05-0.2 | -0.05 | -0.04 |

| Mechanical Property | ||||||||||||

| Alloy | Delivery state performance | Properties after brazing | Potentiometric | |||||||||

| Rp(Mpa) | Rm(Mpa) | A50(%) | Rp | Rm | MV | |||||||

| FA8X16/0.08mm/H14SR | 160 | 180-220 | 0.5 | 50-60 | 150-160 | -800 | ||||||

| Available Fin Sizes | |||

| Fin width/mm | Center distance/mm | Flanged height/mm | Fin opening/mm |

| 23.5 | 7.7 | 1.2-1.6 | 2.0 |

| 28 | 10.5 | 1.3-1.5 | 2.1 |

| 33.5 | 10.5 | 1.4-2.0 | 2.0 |

| 42.5 | 10.5 | 1.4-2.0 | 2.0 |

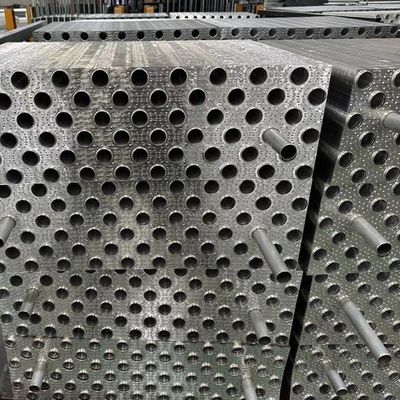

Applications:

Household heat pump and air-conditioning condenser;

Commercial multi-line evaporator, condenser;

Commercial heat pump system (module machine) evaporator;

Bus and car air-conditioning evaporator, condenser;

Commercial air-conditioning duct machine evaporator;

Electric locomotive, rv, truck, engineering vehicle condensers, evaporator;

New energy vehicle air conditioning condenser, evaporator...

Etc.