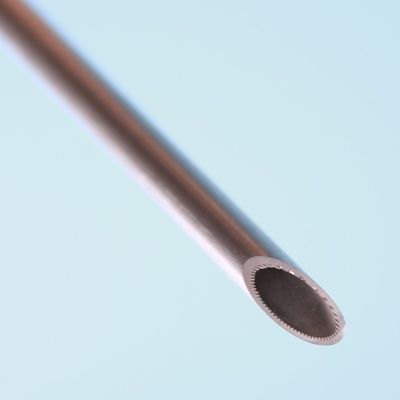

The Reliable Heat Transfer Efficiency Of 3003 Internally Grooved Tube D9.52mm

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO4001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Internally Threaded Pipe | Application | Refrigerating Apparatus,Heat Exchange Equipment |

|---|---|---|---|

| Model Number | 3003 | Outside Diameter/mm | 9.52 |

| Thickness/mm | 0.5 | Tooth Depth/mm | +0.06 |

| TWT/mm | 0.50 | Number Of Teeth | 40-60 |

| Helix Angle/(°) | 18 | Shape | Coil |

| Treatment Process | Oil The Inner Layer | Specification | With Reference To The National Standard Or Customer Requirements, We Can Meet The Customer's Needs For Flaring And Bending, And Can Be Customized To Various Specifications. |

| Details | Tensile Strength>130Mpa, Elongation≥35%, Flaring Rate>40%. Special Production Process, High Density And Efficient Heat Transfer Performance. | Sample | Samples Are Free, Postage Paid By The Customer. |

| High Light | 9.52mm inner grooved tube,heat transfer inner grooved tube,ISO4001 inside threaded aluminum tube |

||

The Reliable Heat Transfer Efficiency Of 3003 Internally Grooved Tube D9.52mm

Product Description:

Heat transfer has been optimized through the use of helical-shaped grooves on the inner surface of the tube. Compared to regular smooth bore tubes, the heat transfer coefficient is twice as efficient. This increased efficiency can benefit the development of smaller heat exchangers and a reduction in refrigerant load. Various groove depths and geometries can be used to accommodate specific refrigerant types and local needs.

Our specialists highly recommend adding a zinc coating to heat exchanger tubes operating in harsh conditions for improved corrosion protection and extended lifespan. This zinc coating is available for both straight inner grooved tubes and smooth bore tubes. When compared to identical tubes without a zinc coating, this additional layer provides superior protection against corrosion.

Features:

* Straight grooves

* High heat transfer efficiency

*Easy shape and bend

* Low cost and weight

* Helical grooves

* Very high heat transfer efficiency

* Low cost and weight

Applications:

condensator

evaporimeter

air conditioner external unit

ice box

refrigerator

Small heat exchanger

frigistor

packaged air conditioner

Dry wet machine

etc.

Techical Parameters:

| Product Name | Model Number (Material) | State | SWAAT>1000 h Ensile Strength>130 Mpa Yield Strength 50-80 Mpa Elongation≥35% Flare>40% | ||||||||

| Outside Diameter/mm | Thickness/mm | Tooth Depth/mm | TWT/mm | Addendum Angle/(°) | Helix Angle/(°) | Number of Teeth/mm | Maximum Length/mm | Shape | |||

| Main Size | 3003 | O | 5-13 | 0.3-0.8 | 0.05-0.25 | 0.35-1.05 | 16-60 | 0-30 | 30-70 | Coil | |

| Example | 7 | 0.47 | +0.25 | 0.97 | 18 | 40-50 | |||||

| 7 | 0.40 | +0.10 | 0.50 | 40-50 | |||||||

| 7.94 | 0.40 | +0.10 | 0.50 | 40-60 | |||||||

| 7.94 | 0.60 | +0.18 | 0.78 | 40-60 | |||||||

| 9.52 | 0.45 | +0.05 | 0.50 | 50-60 | |||||||

| 9.52 | 0.60 | +0.20 | 0.80 | 50-60 | |||||||

Product specifications and performance requirements according to the national standards or customer requirements.

AQ.:

Q1: What kind of material alloy is the product?

A1: Currently, there are 1 series, 3 series, and 6 series aluminum alloy.

Q2: What state and performance of the aluminum pipe can be produced?

A2: can produce from hard state to soft state and interval performance products

Q3: Can I customize the product specifications and requirements?

A3: Different specifications and states can be customized according to the requirements, such as fixed ruler straight pipe and coil pipe

Q 4: What is the minimum starting order volume?

A 4: The minimum order volume is 3 tons.