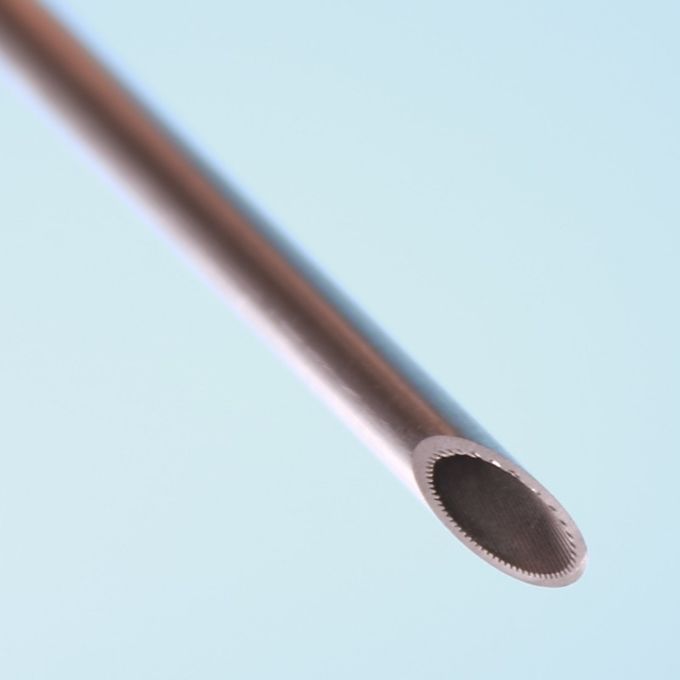

3003 Aluminum Internal Thread Aluminum Tubing Heat Transfer Arear 11mm

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO4001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 metric tons |

| Price | Negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Name | 3003 | Outside Diameter/mm | 11±0.05 Or Customized |

|---|---|---|---|

| Thickness/mm | 0.7±0.03 Or Customized | Tooth Depth/mm | +0.25 Or Customized |

| Number Of Teeth | 45 Or Customized | TWT/mm | 1.01 |

| Addendum Angle/(°) | 16±5 | Helix Angle/(°) | 16±2 |

| Treatment Process | Oil The Inner Layer | Shape | Coil |

| Material | Aluminum Alloy Or Aluminum | Length | Customized |

| High Light | 11mm evaporimeter inner grooved tube,inner grooved tube 11mm,inside threaded pipe ISO9001 |

||

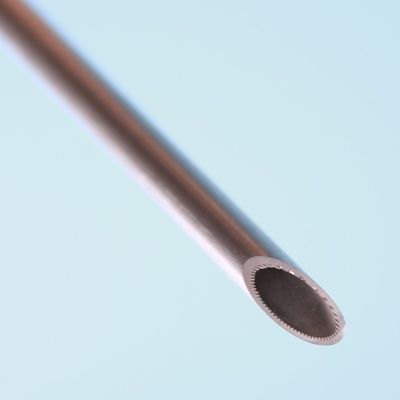

3003 Aluminum Internal Thread Aluminum Tubing Heat Transfer Arear 7mm

Product Description:

Efficient and corrosion-resistant aluminum tubing with internal threading is a highly reliable and effective heat transfer element that is ideal for use as condenser and evaporator flow pipes in various refrigeration equipment. This product is primarily used with refrigerants and other similar mediums. The unique threading and high teeth on the inner surface greatly increase the heat exchange area of the product, reducing reliance on refrigerant and optimizing cost-effectiveness.

Key production specifications are currently available in finished sizes of φ 9.52, φ 7.94, φ 7, φ 5, and other custom sizes available upon request. The inner wall of the threaded pipe can also be oiled according to specific customer requirements.

Crafted from aluminum alloy, this product takes on a silver appearance and arrives in a coil tube format. All aspects of production, from raw materials to finished product, are subject to strict quality control standards in line with a robust quality management system. This ensures that the end product provides optimal stability and the highest levels of quality for our customers.

Features:

Key features of the product include options for thin, high, low, fine, and small tooth shapes to be customized in alignment with customer needs. The tubing is available in two materials: 3003 anti-corrosion aluminum alloy as well as our highly efficient, proprietary anti-corrosion aluminum alloy that exceeds the anti-corrosion properties of 3003 aluminum alloy by ten fold.

When used in the evaporator, threaded aluminum tubing enables strengthened heat transfer, resulting in an increase in heat exchange area, the number of gasification cores, and degree of liquid film turbulence. In the condenser, the tubing can boost the heat exchange area within the tube, reducing the thickness of the refrigerant liquid film between the tooth tops and the tank agent due to the action of surface tension, which encourages the condensant to leave the heat transfer surface.

Technical Parameters:

| duct Name | Model Number (Material) | State | SWAAT>1000 h Ensile Strength>130 Mpa Yield Strength 50-80 Mpa Elongation≥35% Flare>40% | ||||||||

| Outside Diameter/mm | Thickness/mm | Tooth Depth/mm | TWT/mm | Addendum Angle/(°) | Helix Angle/(°) | Number of Teeth/mm | Maximum Length/mm | Shape | |||

| Main Size | 3003 | O | 5-13 | 0.3-0.8 | 0.05-0.25 | 0.35-1.05 | 16-60 | 0-30 | 30-70 | Coil | |

| Example | 7 | 0.47 | +0.25 | 0.97 | 18 | 40-50 | |||||

| 7 | 0.40 | +0.10 | 0.50 | 40-50 | |||||||

| 7.94 | 0.40 | +0.10 | 0.50 | 40-60 | |||||||

| 7.94 | 0.60 | +0.18 | 0.78 | 40-60 | |||||||

| 9.52 | 0.45 | +0.05 | 0.50 | 50-60 | |||||||

| 9.52 | 0.60 | +0.20 | 0.80 | 50-60 | |||||||

Applications:

condensator

evaporimeter

air conditioner external unit

Small heat exchanger

frigistor

packaged air conditioner

Dry wet machine

etc.

Support and Services:

We can provide technical support and services for the use of thread aluminum pipes, including the production of the opening, bending, pipe raising, welding and other rear process technical guidance, assistance in production, etc. Our experienced technicians can assist you with any problems your product may encounter. We also provide regular after-sales service to ensure that your products are always run at the highest efficiency. We are proud of our work and strive to provide the best customer service.

If you have any questions or concerns about the product or your use, please feel free to contact us.