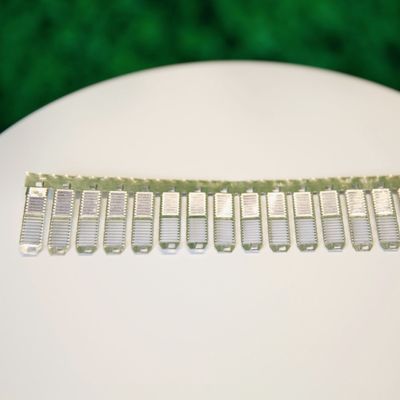

Micro Channel Condenser Aluminum 6815 Louvered Fins Corrosion Resistant 35mm Width

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | YUN NENG |

| Certification | SO9001 ISO14001 ISO45001 |

| Model Number | 6815 |

| Minimum Order Quantity | negotiation |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 6,000w per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

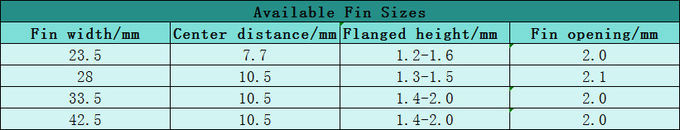

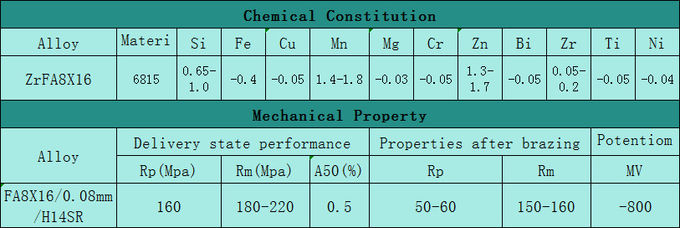

x| Alloy | FA8X16/0.08mm/H14SR | Material | 6815 |

|---|---|---|---|

| Fin Width/mm | 35 | Center Distance/mm | 10.5 |

| Flanged Height/mm | 1.2-1.4 | Fin Opening/mm | 2.0 |

| High Light | Micro Channel Condenser Aluminium Fins,Corrosion Resistant Louvered Fins,Aluminum 6815 Louvered Fins |

||

40mm Aluminum corrosion-resistant fin material 6815 fin width for micro-channel condenser

Product Description:

Aluminum finned tube is a component commonly used in heat exchange equipment such as heat exchangers and coolers. It has the following advantages:

Excellent thermal conductivity: Aluminum has a high thermal conductivity, and the design of fins can increase the surface area of the pipeline, thereby improving heat transfer efficiency. This enables aluminum finned tubes to perform excellently in heat conduction, allowing for faster heat transfer to the pipeline surface and achieving efficient heat transfer.

Lightweight and high-strength: Compared to other commonly used metal materials such as copper and steel, aluminum finned tubes have lighter weight and higher strength. This makes them more convenient in the design and manufacturing process, and reduces the overall weight of the equipment.

Good corrosion resistance: Aluminum finned tubes have good corrosion resistance, especially in humid environments or in contact with certain chemicals. This makes their long-term use more reliable in humid and corrosive environments.

Easy to process and manufacture: Aluminum materials have good machinability and can be manufactured into finned tubes through various processing methods such as extrusion, rolling, etc. This enables aluminum finned tubes to meet the needs of different sizes and shapes to adapt to various application scenarios.

Good appearance and surface treatment: Aluminum finned tubes can be improved in terms of corrosion resistance, aesthetics, and wear resistance through various surface treatment methods, such as anodizing, spraying, etc. This makes them widely used in some applications that require high appearance requirements.

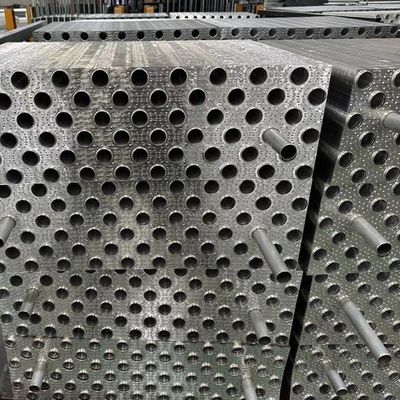

Production Process:

Fin stamping →aggregate→header assembly→press forming→degrease spray (FLUX) drying,

Preheating→(NB) →brazing→ forced air cooling →plastic connection pipe welding →helium leak detection→ultrasonic cleaning→coating→ drying →sheet metal assembly →final inspection→packaging

Techical Parameters:

Household heat pump and air-conditioning condenser;

Applications:

Commercial multi-line evaporator, condenser;

Commercial heat pump system (module machine) evaporator;

Bus and car air-conditioning evaporator, condenser;

Commercial air-conditioning duct machine evaporator;

Electric locomotive, rv, truck, engineering vehicle condensers, evaporator;

New energy vehicle air conditioning condenser, evaporator...

Etc.