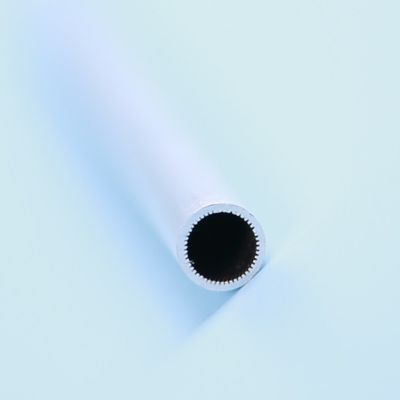

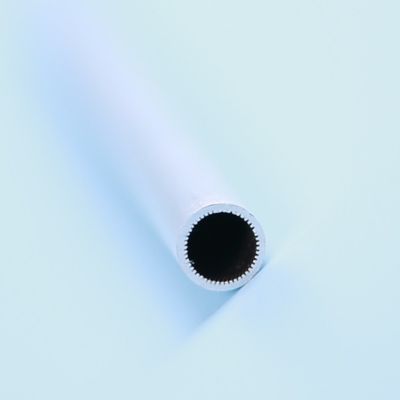

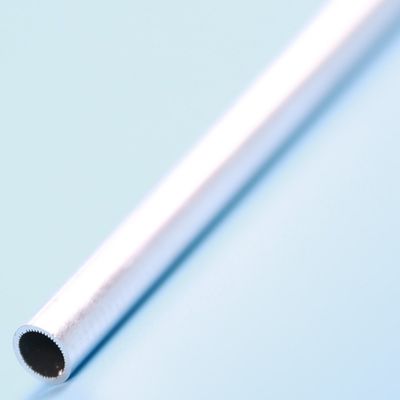

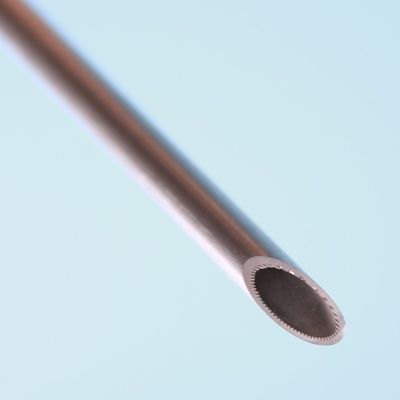

Grooved Aluminum Pipe Heat Exchanger Internal Thread Aluminum Alloy Tubing ECR D7mm

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO4001 ISO45001 |

| Model Number | 3003N |

| Minimum Order Quantity | 3 metric tons |

| Price | negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Internal Thread Aluminum Tubing,Riffled Tubing/Inner Finned Tubing | Application | Refrigerating Apparatus,heat Exchange Equipment, |

|---|---|---|---|

| Model Number | 3003N | Outside Diameter/mm | 7±0.05 |

| Thickness/mm | 0.55±0.03 | Tooth Depth/mm | +0.25 |

| Number Of Teeth | 65 | Shape | Coil |

| Treatment Process | Oil The Inner Layer | ||

| High Light | 3003N 7mm Grooved Aluminum Pipe,Grooved Aluminum Pipe D7mm,Heat Exchanger Tube 65 teeth |

||

Small Heat Exchanger Internal Thread Aluminum Alloy Tubing ECR D7mm

Product Description:

Mechanism of efficient heat transfer performance of internally ribbed tubes:

During evaporation, the heat transfer area on the inner surface is increased. Due to the capillary effect, the wetted area increases; and the ribs inside the threaded pipe are spiral, thus increasing the turbulence intensity of the fluid inside the pipe.

Efficiency:

The use of internally threaded tubes can improve the efficiency of heat exchangers. Tubes with threaded tube grooves on the inner wall have higher heat transfer coefficients than normal smooth-walled tubes. The internal threaded tube was developed abroad from 1978. Currently in Japan, it has rapidly replaced the traditional smooth tube. At present, the use of internal threaded pipe in domestic air conditioners is more than 40%, and in commercial air conditioners has exceeded 50%.

Cost:

The use of internally threaded tubes can reduce the amount of aluminum tubes, aluminum heat sinks, and frame construction materials needed for the refrigeration system; reduce the refrigerant charge; reduce the power of the compressor and fan; and also increase the energy-efficiency ratio, which reduces the amount of electricity consumed; and improve the heat transfer performance of the transverse ribbed coil.

Applications:

condensator

evaporimeter

air conditioner external unit

Small heat exchanger

frigistor

packaged air conditioner

Dry wet machine,

etc.

Technical Parameters:

Efficient Corrosion Resistant Aluminum Alloy Tubing

| Product Name |

Model Number (Material) |

State | SWAAT>1000 h Tensile Strength 95-130 Mpa Yield Strength 50-80 Mpa Elongation≥32% Flare>40% | ||||||||

| Outside Diameter/mm | Thickness/mm | Tooth Depth/mm | TWT/mm | Addendum Angle/(°) | Helix Angle/(°) | Number of Teeth | Shape | ||||

| Main Size | 3003 | O | 5-13 | 0.3-0.8 | 0.05-0.25 | 0.35-1.05 | 16-60 | 0-30 | 30-70 | Coil | |

| Example | Normal D7 | 3003 | 7±0.05 | 0.47±0.03 | +0.25 | 0.97 | 18±5 | 18±2 | 50 | ||

| ECR D7 | 3003N | 7±0.05 | 0.55±0.03 | +0.25 | 0.80 | 28±5 | 28±2 | 65 | |||

| ECR D5 | 5±0.05 | 0.35±0.03 | +0.20 | 0.55 | 20±5 | 20±2 | 45 | ||||

| ECR D7 | 7±0.05 | 0.40±0.03 | +0.20 | 0.60 | 25±5 | 25±2 | 65 | ||||

Support and Services:

We can provide technical support and services for the use of thread aluminum pipes, including the production of the opening, bending, pipe raising, welding and other rear process technical guidance, assistance in production, etc. Our experienced technicians can assist you with any problems your product may encounter. We also provide regular after-sales service to ensure that your products are always run at the highest efficiency. We are proud of our work and strive to provide the best customer service.

If you have any questions or concerns about the product or your use, please feel free to contact us. We will always give you the answers you need.

FAQ.:

FAQ.:

Q1: What kind of material alloy is the product?

A1: two materials are available, 3003 anti-corrosion aluminum alloy material and 30588 efficient anti-corrosion aluminum alloy material.

Q2: Product final status?

A2: The final state of the product is soft aluminum coil, threaded pipe inner surface can be coated with inner rising tube oil

Q3: Can I customize the product specifications and requirements?

A3: Different materials and products with different requirements can be customized according to the requirements

Q 4: What is the minimum starting order volume?

A 4: The minimum order volume is 3 tons.