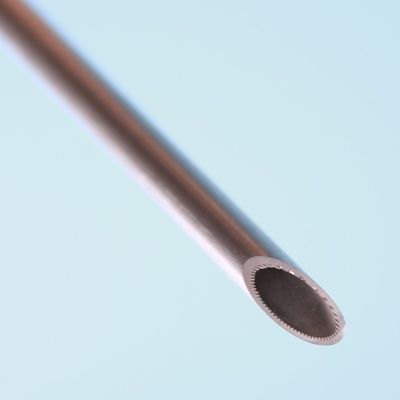

The Heat Transfer Grooved Aluminum Pipe 3003 Aluminum Inside Threaded Aluminum Tube 9.5mm

| Place of Origin | Changzhou China |

|---|---|

| Brand Name | Yun Neng |

| Certification | ISO9001 ISO4001 ISO45001 |

| Model Number | 3003 |

| Minimum Order Quantity | 3 metric tons |

| Price | Negotiation |

| Packaging Details | Standard export packaging |

| Delivery Time | 30 working days after received your down payment |

| Payment Terms | T/T |

| Supply Ability | 50,000 mt per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Na | 3003 | Outside Diameter/mm | 9.5±0.05 Or Customized |

|---|---|---|---|

| Thickness/mm | 0.5±0.03 Or Customized | Tooth Depth/mm | +0.23 Or Customized |

| Number Of Teeth | 50 Or Customized | TWT/mm | 0.9 |

| Addendum Angle/(°) | 21±5 | Helix Angle/(°) | 21±2 |

| Treatment Process | Oil The Inner Layer | Shape | Coil |

| Material | Aluminum Alloy Or Aluminum | Length | Customized |

| High Light | evaporimeter Grooved Aluminum Pipe,9.5mm Grooved Aluminum Pipe,inside threaded aluminum tube 9.5mm |

||

The heat transfer area of aluminum tube 3003 aluminum internal thread aluminum tube is ar9.5mm

Product Description:

Our 3003 Internal Threaded Aluminum Tubing is a reliable and efficient heat transfer element suitable for use in various refrigeration equipment as an evaporator or condenser flow pipe. It is primarily used with refrigerants and other related fluids. The unique thread design and high teeth on the inner table increase the heat exchange area, which reduces the use of refrigerants, optimizing overall costs.

We offer finished products in specifications such as φ 9.52, φ 7.94, φ 7, and φ 5, but we can customize specifications and performance requirements according to customer needs. The inner wall of the threaded pipe can be oiled to meet the requirements of the rear road rise pipe process products. The product is made of aluminum alloy, which gives it a silver appearance. Our strict quality control standards ensure that every production process is closely monitored.

Features:

Our product offers a range of different tooth shapes such as thin, high, low, fine, and small teeth, which can be customized to meet specific usage needs.

The product is available in both 3003 anti-corrosion aluminum alloy and our unique high-efficiency anti-corrosion aluminum alloy. The anti-corrosion effect of the latter is 10 times better than that of the former.

The threaded aluminum tube can improve heat transfer in the evaporator by increasing the heat transfer area and the number of gasification cores, as well as increasing the turbulence degree of the liquid film. In the condenser, the threaded aluminum tube increases the heat transfer area, forcing the condensate to leave the heat transfer surface, and reducing the thickness of the refrigerant liquid film between the tooth top and the tan.

Technical Parameters:

Internal Thread Aluminum Tubing

| Product Name | Model Number (Material) | State | SWAAT>1000 h Ensile Strength>130 Mpa Yield Strength 50-80 Mpa Elongation≥35% Flare>40% | ||||||||

| Outside Diameter/mm | Thickness/mm | Tooth Depth/mm | TWT/mm | Addendum Angle/(°) | Helix Angle/(°) | Number of Teeth/mm | Maximum Length/mm | Shape | |||

| Main Size | 3003 | O | 5-13 | 0.3-0.8 | 0.05-0.25 | 0.35-1.05 | 16-60 | 0-30 | 30-70 | Coil | |

| Example | 7 | 0.47 | +0.25 | 0.97 | 18 | 40-50 | |||||

| 7 | 0.40 | +0.10 | 0.50 | 40-50 | |||||||

| 7.94 | 0.40 | +0.10 | 0.50 | 40-60 | |||||||

| 7.94 | 0.60 | +0.18 | 0.78 | 40-60 | |||||||

| 9.52 | 0.45 | +0.05 | 0.50 | 50-60 | |||||||

| 9.52 | 0.60 | +0.20 | 0.80 | 50-60 | |||||||

Applications:

condensator

evaporimeter

air conditioner external unit

Small heat exchanger

frigistor

packaged air conditioner

Dry wet machine

etc.